If the ratio of feed material and end product size is 16 1 you need 2 crushers and this is calculated by multiplying 4 with 4 If the ratio would be let s say 20 1 you would need 3 crushers Some easily crushable rock types can be crushed in two stages and some harder rock types in turn require to be processed in three stages or more

Get PriceDuring the process of operation the material is crushed and ground and the crushing will be done While when the jaw is going down the angle will certainly become smaller the moving jaw plate will leave the fixed jaw plate on account of the effect of pulling bar and spring and then the crushed material will be discharged from the lower opening of the crushing room

Get PriceBut despite the larger upfront investment Haddix says a used mobile crushing plant is much more resaleable compared to a stationary plant Additional benefits of mobile crushers include short planning and installation time reduced in pit transport costs and added on site flexibility Haddix says Mobile equipment can also be more easily

Get Price4 Lubricate your machine regularly Lubricate important parts like mainshaft bearings mantle and concave can make the whole production smooth and minimize the downtime 5 Clean your oil tank if it is contaminated 6 Remove the fines or sticky material in the crushing chamber

Get PriceProduct Price Rs Lakh / Unit Get Best Price We are presenting Jaw Crusher from our broad assortment of Industrial Crushers These are extensively used in mining road construction metallurgical industries and so forth It offers even composition of output and is simple in construction with low operating costs

Get PriceWith today s technology in track mounted crushers producers maintain production requirements and reduce overhead costs which in turn reduces cost per ton of material produced Paul Smith director of international sales marketing for Astec Aggregate and Mining Chattanooga spoke in terms of moving volume of material

Get PriceWith cone crushers though it is essential to operate them at consistent choked settings to keep productivity up 3 Tertiary/Quaternary/Final Reduction Crushing The goal of the tertiary third quaternary fourth or final reduction stage of the crushing process is to size and shape rock or other material into a marketable product

Get PriceCone crushers can form finished products down to 12mm or less Like the jaw crusher the cone crusher provides a relatively low cost crushing solution but there are application drawbacks which may make another crushing solution more appealing First cone crushers cannot accept all material sizes

Get PriceResults The 18% manganese liners used prior to the trials lasted for a maximum of 12 weeks 16 800 tonnes through crusher The first trial liners using hardfacing lasted 38 weeks 53 200 tonnes through crusher providing 216% extra life As this proved such a success it was decided correctly that a lower cost manganese could be used

Get PriceHP 300SX cone crusher with chassis includes switchgear and cords Belt is 36 inches Replaced eccentric bushings counterweight guard socket socket ball socket bushing Condition Used L x W 43 x MLS Number 11255297

Get PriceThis is known as the reduction ratio The crushing motion is by means of a flywheel that causes the moving jaw to swing The moving jaw can have either single or double toggles fitted which give

Get PriceWith cone crushers though it is essential to operate them at consistent choked settings to keep productivity up 3 Tertiary/Quaternary/Final Reduction Crushing The goal of the tertiary third quaternary fourth or final reduction stage of the crushing process is to size and shape rock or other material into a marketable product

Get PriceA typical example of secondary crushing is reducing topsize from 300 to 100 mm 3 a typical example of fine crushing is producing concrete aggregates in fractions below 30 mm 4 Manufactured sand is typically smaller than 5 often 2 mm 5

Get PriceHammer impact crusher The feed is fragmented by kinetic energy introduced by a rotating mass the rotor which projects the material against a fixed surface causing it to shatter causing further particle size reduction This crusher produces more rounded shape •

Get PriceCompression crushing quick facts 1 The output is changed by adjusting the gap setting at the discharge point of the crusher 2 Rule of thumb Twice the setting is the top size discharging from the crusher 3 The tighter the setting the lower the throughput 4 Material breaks to fill the air pockets or voids in the crushing chamber

Get PriceAggregate processing plants involves several processing stages such as crush screen store and transfer nonmetallic minerals such as stone sand gravel recycled concrete and asphalt etc The machines applied includes aggregate crushing plant grinding mill screening operation bucket elevator belt conveyor storage bin etc

Get PriceA jaw crusher in a RAP circuit is used for primary reduction prepping it for the cone and requiring at least two crushers and in some instances a vertical shaft impactor VSI to make a spec product An impactor in most RAP applications typically requires only one crusher

Get PriceCrusher type Primary crushers Secondary and tertiary crushers Main purpose Size reduction Size reduction cubicity and breakage of microfractured particles Production line Open circuit Secondary open circuit tertiary closed circuit Reduction ratio 2 1 to 10 1 3 1 to 10 1 2 1 to 8 1 3 1 to 7 1 2 1 to 6 1 Fines mm percentage of feed

Get PriceJaw crushers are generally considered a primary or first stage crusher The maximum feed size can be as large as 80% 85% of the crusher s gape or depth while reduction ratios range from 2 3 times Cone crushers are typically used in the secondary or tertiary stage after a jaw crusher s begun the reduction process earlier in the circuit

Get PriceFor better control of the aggregate particle size distribution it is recommended that the CDW should be processed in at least two crushing stages First the demolition methodologies used on site should be able to reduce individual pieces of debris to a size that the primary crusher in the recycling plant can take

Get PriceAggregate crushers screeners and conveyors For the most cost effective crushing Frontline offers Keestrack s top impact jaw and cone crushers The Keestrack R6 impact crusher is perfect for high production and high capacity with a long aggressive pre screen and an optional 2 deck after screen producing up to 500 tonnes an hour

Get PriceThe power costs associated with size reduction can account for more than half of the operating costs of a mineral processing plant Even small improvements in the energy efficiency of a crusher can have a significant effect on the economic performance of an entire plant

Get PriceA jaw crusher is used at the beginning of the aggregate crushing process in the primary crushing stage to crush the largest boulders Jaw crushers can crush all types of rock including the hardest granite brick concrete and asphalt Ethiopia stone jaw crusher has high reduction ratio and increased capacity with any feed materials

Get Pricerate reduction mill 55 22 bugnot bve the fabrication carbonisation charbon de typha drilling process for iron ore rate reduction mill 55 22 bugnot bve theGet mill bugnot bve china mill sewri work list spkpfoundationorg china 0 stone ball mill machine ball mill ball mill bond work SCM Power Mining Crusher rate

Get Pricehigh crusher ratio and production efficiency manifold crushing cavity crusher and grinder ball milling process grinding mill for sale in Pakistan gravel machine sand maker sand making plant The machine is a patented product developed on the basis of our former sand making machines … aggregate plants glass factories hydropower stations …

Get PriceRegarded as the main process in aggregate production crushing is the first controlled size reduction stage and is the basis for optimal further size reduction It is therefore important that when choosing a new rock crusher the first thing you need to know is which one best matches your material and it is imperative to find the right one

Get PriceEfficiency can be defined by the ratio of a machine s work to the energy supplied to the machine To apply what this means to your crusher operations produce the exact sizes in the reduction process that their market demands In the past quarries produced a range of single size aggregate products up to 40 mm in size

Get PriceThe size reduction process of rocks in cone crushers is one of the most important issues particularly for the secondary and tertiary stages of crushing operations

Get PriceThis process of size reduction is called comminution The crushing and grinding process will produce a range of particles with varying degrees of liberation Figure 2 Any particles that exceed a target size required for physical separation or chemical extraction are returned to the crushing or the grinding circuit

Get PriceAIHP Series Primary AGGRETEK AIHP crushers offering high reduction ratios reduced power consumption easier and safer maintenance are the solution for operating conditions where output and productivity demands are increasingly stringent The strength of AIHP crushers makes them ideal for diverse applications and configurations

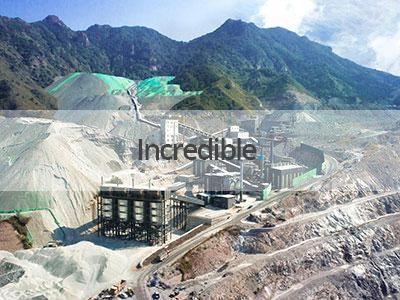

Get PriceIncredible has successfully built lots of crushing plants, grinding plants and metal ore dressing plants for our customers.

With over 30 years of experience, we become a renowned manufacturer in the stone crushing and mineral grinding industry. Headquartered in Shanghai, China, our expansive factory spans over 120 hectares, empowering us to cater to the production demands of global customers.