the lime based on testing to Section 28 of ASTM C25 06 2 TERMINOLOGY Quicklime also known as burnt lime is normally a granulated material which has calcium oxide CaO as the active ingredient It can be supplied as fines granules or lump material Hydrated Lime also known as slaked lime is a powdered material which has

Get PriceBurning calcination of calcium carbonate in a lime kiln above 900 °C 1 650 °F converts it into the highly caustic material burnt lime unslaked lime or quicklime calcium oxide and through subsequent addition of water into the less caustic but still strongly alkaline slaked lime or hydrated lime calcium hydroxide Ca OH 2 the process of which is called slaking of lime

Get PriceIron works produce hydrated lime as flus for sintering Dust Collector 1 widely use To deal with the dust and harmful gases produced in the process of lime hydration of steel Iron plants power plants chemical plants etc 2 principles and features It can meet the needs of a variety of processes

Get PriceBurnt lime has been crucial for architectural dietary and other purposes in Maya society since as far back as 1100 BCE The recent identification of a series of pit kilns used for lime production in the Puuc region of the northern Yucatán Peninsula allows for an unprecedented investigation of the socio economic organization of the Pre Columbian lime industry

Get PriceAbout Us We Malik Lime Chemicals established in the year 2024 are involved in Manufacturing a range of Lime Powder Burnt Lime Wall Putty We strive hard to attain the utmost contentment of customers and in this process We always keep on adding the best in our product portfolio

Get PriceThe Limestone is calcined burnt in either of our two rotary kilns or two shaft kilns at temperatures of between 900 1200 degrees centigrade during which time the carbonate is converted into oxide CaO or CaMgO2 and CO2 is released Burning is the key process in the production of lime converting stone into a product that is widely used in

Get PriceHARD BURNT LIME Lime products made of limestone fed to the furnace with higher temperature They are particularly used in lightweight concrete block industry Watch the whole production process of our lime products in this video ชมวีดีโอกระบวนการ การผลิตปูนขาวคุณภาพ

Get Price3 Given below is a process description Read it and draw a flow chart representing the process described Rayon is a man made fibre It is a reconstituted natural fibre cellulose Rayon is made by dissolving cellulose in a solution of sodium hydroxide or caustic soda The cellulose is obtained from shredded wood pulp

Get PriceThe natural process involves spreading them in uniform columns in an open space Ensure there s ample air circulation between bricks for optimal drying This should take at least 10 days depending on the weather The artificial drying process is preferred for large scale production and in wet environments Special dryers are used to dry the

Get PriceThe mould is then lifted up and raw brick is left on the ground The mould is dipped in water and it is placed just near the previous brick to prepare another brick The process is repeated till the ground is covered with raw bricks A brick moulder can mould about 750 bricks per day with working period of 8 hours

Get PriceThe manufacturing process aims to produce a material with a high content of tricalcium silicate usually 55 to 62% of the crystals in the clinker Other crystals formed are about 15% dicalcium silicate the same component as the hydraulic binder in hydraulic lime 8 to 10% tricalcium aluminate and 9% tetracalcium aluminate ferrite

Get PriceBurnt Lime and Dolime Carmeuse is a global leader in supplying High Calcium lime for Steel Making operations Carmeuse owns state of the art kilns and uses the best practices to operate these kilns to provide the best quality high calcium lime and dolomitic lime based products Our Burnt Lime and Dolomitic Lime products have optimum sizing the highest purity of CaO content and low CO2 content

Get PriceLime slaking The Burnt Lime or Quicklime is then combined with water slaked as quickly as possible From the moment it is burnt the material starts to degrade by air slaking Combining Quicklime CaO and water H20 produces Calcium Hydroxide Ca OH 2 slaked lime and heat There are three main ways of slaking the Quicklime

Get PriceThe subject of the invention is a process for the production of pure burnt lime using gaseous fuels produced from energy carriers in particular industrial wastes wherein the energy carriers are gasified in an installation consisting of a fluidized bed and a cyclone and the noxious substances released during the thermal decomposition are separated off by means of adsorbents before they come

Get PriceFeb 1 2022By Gerald Ondrey February 1 2024 Decomposing limestone CaCO 3 into quicklime burnt limestone CaO releases significant CO 2 emissions both from the combustion of fuel needed to heat the kiln to temperatures over 1 000°C and by the release of CO 2 from the reaction itself CaCO 3 → CaO CO 2

Get PriceBurnt lime calcium oxide Also know as quicklime burnt lime is derived by heating limestone to drive off carbon dioxide It is more concentrated and caustic than agricultural lime and unpleasant to handle so is rarely used in agriculture Calcium Oxide CaO is mainly used in the production of cement

Get PriceThe Rotary Kiln The rotary kiln is the key component in a cement plant It is a long steel cylinder lined with refractory brickwork to protect the outer shell from the high temperatures of the interior The kiln is very large up to 4 m diameter and up to 50 m long It typically rotates three to five times per minute

Get PriceOur Hydrated Lime is XRF tested to ISO accredited standards at our in house process control laboratory at a series of points throughout the manufacturing process and again at dispatch Hydrated lime is a high purity fine white powder which is commonly known as slaked lime Applications include water treatment production of plasters and

Get PriceBurnt Lime Manufacturing Process Machine Common Fault 1 Hammer Failure The crushing function of lime is mainly realized by the series of impact impact shearing and extrusion of the hammer head and the lining of the Burnt Lime Manufacturing Process Machine and the lime The hammer head is the main wearable part

Get PriceHalf burnt dolomite CaCO is also called calcium magnesium carbonate oxide dolomite calcined Refining is the removal of impurities in general and in the lime manufacturing process the term is also used for milling hydration or milk of lime lime slurry production

Get PriceMr Xie Jun Dumisani Nsingo Senior Reporter CHINESE firm Ming Chang Sino Africa Mining Investments has started lime production at its $4 million state of the art plant in Bubi District Matabeleland North Province Ming Chang plant manager Mr Xie Jun said the company started production and marketing its lime last month

Get PriceA lime kiln is a kiln used for the calcination of limestone calcium carbonate to produce the form of lime called quicklime calcium oxide The chemical equation for this reaction is CaCO 3 heat → CaO CO 2 This reaction can take place at anywhere above 840 °C 1544 °F but is generally considered to occur at 900 °C 1655 °F at which temperature the partial pressure of CO 2 is 1

Get Pricethe unslacked lime Burnt Lime With Oil Firing and Pollution Control System PRODUCT CODE 21126 21127 and 21131 QUALITY AND STANDARDS IS 1886 1961 IS 712 1973 IS 1624 1974 PRODUCTION CAPACITY Quantity 9 000 per annum Value Rs 2 02 50 000 MONTH AND YEAR January 2024 OF PREPARATION

Get PriceLime is made by the process of cakining limestone that is burning Che limestone without fusing melcing it Pure lime quicklime burnt lime caustic lime is composed of calcium oxide When with water lime gives off heat forming calcium hydroxide and is sold commercially as slaked or hydrated lime

Get PriceSand Lime 1 Burnt Clay Brick The classic form of brick is the burnt clay These types of brick are created by pressing the wet clay into the molds then these are drying and firing in the kilns Manufacturing Process There are four steps involved in the manufacturing process 1 Preparation Of Clay For the preparation of the bricks we

Get PriceShri Ram Industries is an ISO 9001 2024 Company engaged in Manufacturer and Supplier of Quick Lime Moisture Powder Anti Moisture Powder Burnt Limestone Hydrated Lime Powder Quick Lime Powder and Limestone are aimed at offering high quality products to meet the overall time requirement of various industries The determination and team effort has earned the company a name in the

Get PriceBurnt Lime also called as quick lime or unslaked lime is made out of lime stone deposits which are wide spread throughout the country Process of Manufacture kilns and its manufacture IS 712 1973 Methods of testing for building lime IS 1624 1974 Fields testing and building lime and mortars Production Capacity per annum The production

Get PriceIt was discovered that limestone when burnt and combined with water produced a material that would harden with age The earliest documented use of lime as a construction material was approximately 4000 when it was used in Egypt for plastering the pyramids ref ii The beginning of the use of lime in mortars is not clear

Get PriceClass A Eminently Hydraulic Lime It is available in hydrated form and can be used for structural works like arches domes etc Class B Semi hydraulic Lime It is available as both quick lime and hydrated lime This mortar is used for masonry works Class C Fat Lime It is available in quick or hydrated form

Get PriceFlyash Bricks is a building material specifically masonry units containing fly ash and water compressed at 28 MPa 272 atm and cured for 24 hours in a 66 °C steam bath then toughened with an air entrainment agent 2 1] To provide and promote business and services that strengthens the brick manufacturing sector for the ultimate benefit of

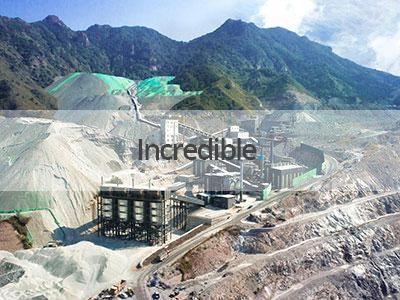

Get PriceIncredible has successfully built lots of crushing plants, grinding plants and metal ore dressing plants for our customers.

With over 30 years of experience, we become a renowned manufacturer in the stone crushing and mineral grinding industry. Headquartered in Shanghai, China, our expansive factory spans over 120 hectares, empowering us to cater to the production demands of global customers.