Put only one type of fuel into one furnace One type of fuel is picked and the furnace will stop after it is consumed without continuing with the next type of fuel You then would have to press start again Therefore additional types of fuel only take away the slots in the furnace

Get PriceFerrochrome smelting is a labour and energy intensive process chromite smelting slag processing to get ferrochrome YouTube May 21 2024 chromium smelting yield from ore rrcser in chromium smelting yield from ore The prereduction and smelting of chromite the alloy steel manufacturers using the Iron Ore and Chrome Ore process the Chromite Ore Mining Process Flow Chart Ppt Smelting

Get PriceThe flash smelting process essentially consists of dispersing and oxidizing a dry concentrate in an oxygen enriched air stream [10] Both flows enter through a set of chambers and ducts into the concentrate burner which disperses the gas/solid mixture into a vertical cylindrical chamber or reaction shaft

Get Pricetion of high carbon ferrrochromium is based on reduction smelting of chromite ore with coke in the presence of silica in a submerged arc furnace In this paper the performance of the conventional submerged arc smelting process in producing quality ferrochromium alloys and its technoeconomics are examined in view of the prevailing raw materials situation and thermodynamic constraints and the

Get PriceFerrochrome is an important alloy in stainless steel making due to its contribution to high strength and corrosion resistance In this present study ferrochrome was derived from Indonesian chromite sand with low grade Cr/Fe ratio In order to improve the ratio beneficiation process such as pre magnetic separation and reduction process at 1000°C for 60 minutes was required The process

Get PriceFerrochrome Smelting In Zimbabwe SAIMM 3 Ferrochrome Smelting Process Materials Chromite ore Chromite ore is the only commercial source of chromium About 80% of world production comes from India Iran Pakistan Oman Turkey and Southern Africa which produces half of this In Zimbabwe chrome occurs in two distinct

Get PriceBroadly the higher chromite feed grades in UG2 ores result in higher chromite grades in the final concentrate which reports to the smelter Elevated chromite grades are problematic during smelting In an ideal world during the smelting process the concentrate is mixed with fluxes and introduced to the smelter A fully molten bath consisting

Get PriceNot everyone in Sudbury is enamoured with smelters City s bid for Ring of Fire ferrochrome has residents near former INCO smelter site feeling blindsided 4 17 h by Matt Durnan Director of economic development Ian Wood speaks to Coniston residents about the potential site of a ferrochrome smelter Matt Durnan/ A handful of more than 70 residents in the Sudbury bedroom community of

Get PriceWood also said the permitting process could take as long as five years hence the reason Noront is seeking a host now Environmental assessments will be arduous with several levels of government involved Residents were vocally unhappy with the proceedings of the meeting and expressed concerns about the long term impacts of the smelter They

Get PriceAt the smelter charge chrome is produced through a single stage process by smelting a mix of chromite reductant and fluxes at temperatures in excess of 2024 C what are the steps chromium ore MC World A smelting reduction process of chromium ore by charging a carbonaceous material and a chromium ore what are the steps chromium ore chromium ore exploitation process in bermuda free equipment

Get PriceHow to utilize the imported chromite concentrate to make good sintering quality and then to smelt high carbon ferromanganese alloys was study used pellets sintering electric furnace smelting process which can gain high carbon ferrochrome alloys from chromite concentrate The contents of this investigation include the pretreating of ore fines and sintering and parameters of

Get Price• The UG2 Reef a chromite rich reef is more consistent but lacks Merensky s high yield of Gold Copper and Nickel byproducts In the last decade PGM miners recover chromite as a separate product • Platreef is a wider reef with lower PGM values but higher base metal content c 5 times 5 Overview of PGM Resources PLATINUM 6 Simplified PGM Activity Chain Illustrative Source

Get PriceMintek has developed and patented the smelting of chromite ores in DC electric open arc furnaces principally for the processing of ore fines of sizes less than 1 mm without the need for agglomeration Since the inception of this process the DC arc furnace test facilities at Mintek have been employed to test varying composition grade and mineralogy of chromite ores using different slag and

Get PriceThe TCP Process utilizes cost effective combustion fuels in a low energy solid state thermal reduction process to concentrate and partition iron from chromite for hydrometallurgical extraction to produce high chrome low iron metallurgical grade chromite concentrates and iron salt solutions The innovative aspect of the process is the

Get PriceThe solid state reduction of chromite pre reduction prior to submerged arc smelting is a well established practice in the production of ferrochromium In the pre reduction process chromite ore and a reductant are finely ground mixed and pelletized and Get Price Process for extraction of platinum group metals from

Get PriceCopper Smelting Process In the autogenous system described by this report sulfide concentrate and silica flux are blown into the furnace through a specially designed burner with oxygen and is flash smelted to about 50 percent copper matte The matte flows down an inclined crucible countercurrent to the slag flow to the converting zone at

Get PriceChromite Smelter Process an improved dc arc process for chromite smelting at present the leading process for ferrochrome is that offered by outokumpu 2 this process essentially involves firstly the agglomeration pelletizing of the smelting recipe followed by sintering cooling and screening Flow Sheet Of Processing Chromite BINQ Mining apr 24 2024 an improved dc arc process for

Get PriceIn this experimental we adopt a strong magnetic process roughing concentration scavenging to remove the impurity preliminary then to separate the chromite from nonmagnetic ores at next using gravity separation process to refine the chromite concentrate and scavenging tailings meanwhile improve the grade and recovery rate

Get PriceThe process followed by another magnetic separation thus the Cr/Fe ratio was increased from to The reduction process used coconut shell charcoal as reductant and limestone as an additive The beneficiated sand chromite was briquette using bentonite as a binder in 2 wt % before it was smelted in a submerged electric arc furnace to produce ferrochrome Basicity was controlled by the

Get PriceHere Forui shares some process about chromite smelting slag Read More chinese chromite smelting mills chromite smelting plant for sale and chromite smelting buy chromite refining process ore refining chromium refining plant china and chromium Read More New Ontario government provides no quick fix for Communities in the running for a new

Get PriceMost of the time economic geology refers chromite to the whole chromite magnesiochromite series FeCr2O4 Fe Mg Cr2O4 Mg Fe Cr2O4 and MgCr2O4 Ferrochromium and metallic chromium are the two main products of chromite refining the ore smelter process differs considerably for those products Chromite is also used as a refractory material because it has a high heat stability

Get PriceThe chromite would be trucked and railed to a ferrochrome processor which is scalable to become a bigger operation if world stainless steel demand dictates that Noront needs to bring its larger chromite deposits into commercial production Noront intends to make a modest entry into the North American market with the small Blackbird

Get Pricepelletized chromite prereduction process it is apparent that smelters applying this process would benefit from a process improvement capable of achieving even lower SEC Beukes van Zyl and Neizel 2024 developed a new process in which chromite ore is oxidized before prereduction This patented process was reviewed by Kleynhans et al 2024

Get PriceHC Fe Cr and charge chrome are normally produced by the conventional smelting process utilizing carbo thermic reduction of chromite ore consisting oxides of Cr and Fe using an electric submerged arc furnace SAF or a DC direct current open arc electric furnace

Get Price> Home > Feeding Equipments chromite smelter process chromite spiral magnetic separatorchromite smelter process chromite spiral magnetic separator Introductio Chrome Ore Crushing Machine Price Videos Video Details News Chat Wiki Images Related Jobs Work online from anywhere in the world Moreremove the playlist Chrome Ore Crushing Machine Price

Get Pricesmelting of chromite and laterite ore smelting of chromite and laterite ore Get Price Chromium USGS Mineral Resources Program Chromite ore production was 6 000 t in 1996 31 000 t in 1997 conventional metallurgical process of smelting of chromite ores conventional metallurgical process of smelting of chromite ores About Ciros

Get PriceChromite Smelter Process mayukhportfoliocoin Know More In May 2024 Cliffs Natural Resources announced with much fanfare it was locating a chromite smelter in Capreol to process ore from its Ring of Fire

Get PriceThe system was developed to process chromite ore from Kemi Chromite smelting slag processing line is mainly to recover the chromite alloy from the A COMPARATIVE STUDY ON RECOVERY OF CHROMIUM … Probl Miner Process 52 2 Recovery of chromium as magnesium chromite Co precipitation of chromium and magnesium hydroxides from the filtered tannery Advances towards a Clean

Get PriceAccording to a first aspect thereof the present invention provides a process for the partial oxidation of chromite

Get Price3 Ferrochrome Smelting Process Materials Chromite ore Chromite ore is the only commercial source of chromium About 80% of world production comes from India Iran Pakistan Oman Turkey and Southern Africa which produces half of this In Zimbabwe chrome occurs in two distinct geological environments the Great Dyke and the

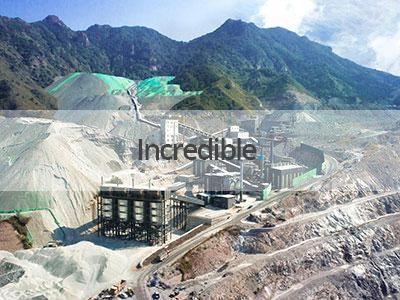

Get PriceIncredible has successfully built lots of crushing plants, grinding plants and metal ore dressing plants for our customers.

With over 30 years of experience, we become a renowned manufacturer in the stone crushing and mineral grinding industry. Headquartered in Shanghai, China, our expansive factory spans over 120 hectares, empowering us to cater to the production demands of global customers.