Jul 1 2021In pit Crushing and Conveying IPCC as a driver of reduced mining costs and reduced emissions Background In a time where a open pits are getting deeper requiring lower mining cost solutions and b there is increasing pressure on mining companies to reduce carbon emissions

Get PriceAn innovative technological approach to skip haulage could optimize costs and energy efficiency in hard rock mines Open pit metal mines are often shaped like an inverted cone with the ore and overburden being drilled and blasted then loaded and transported by shovel and truck systems Mine trucks that weigh between 106 and 260 tons and

Get PriceThe extraction of nickel process generally consists of crushing sieving washing re selection grinding and slurry concentration or the nickel leaching method The target element nickel distribution varies with the nature of the ore mostly contained in fine grained grades For example the nickel minerals of the Ramu laterite mine in Papua

Get PriceThe in pit crushing is not only a mean to facilitate conveying but should be seen as an integrated part of the comminution process A mobile solution also makes it easier to manage ore blending which is often required By doing much of the crushing already in the pit substantial savings can be made in the downstream process

Get PriceThe latest in pit crushing and conveying articles from Mining Magazine Page 2 Home Surface mining Development Fleet Technology / Innovation Operational excellence The new Sandvik PF300 in pit mobile crushing system is primarily designed for large scale surface Equipment 09 APRIL 2024

Get PriceHAIYAN SUNFAST CHINA We are the leading Stone quarry mining crushers from east stone crushing plants are running well and

Get Priceopen pit mine quarry with conveyor belts crushing stones mining crusher stock pictures royalty free photos images Mongolian worker looks out from operations along the blue conveyor belt that moves rock from the crusher to the concentrator area at the Oyu

Get PriceIn pit Crushing and Conveying IPCC as a driver of reduced mining costs and reduced emissions Background In a time where a open pits are getting deeper requiring lower mining cost solutions and b there is increasing pressure on mining companies to reduce carbon emissions

Get PriceIn Pit Crushing Conveying IPCC is a general term for a more continuous mining process In open pit mining of soft rock a bucket wheel excavator carries out the tasks of loosening and loading directly in situ because the extraction does not require blasting and the material s compressive strength is low

Get PriceThyssen Krupp Industrial Solutions has received a contract from Apatit to supply a complete in pit crushing and conveying IPCC system for an apatite nepheline ore mine The mine is located near the city of Kirovsk on the Kola Peninsula in northern Russia The order is worth around 30 million Essen/Germany The contract awarded to

Get PriceDump trucks haul the rock to the primary crushers in the open pit or to the ore stockpiles from underground 2 Crushing — The primary crushers located at the open pit mine site receive ore and waste at separate times They break the larger rocks down to a size suitable for transport on the conveyor belt 3

Get PriceInternal waste dump refers to discharging the rock and soil into the goal of the open pit mine directly which is the most economical method of dumping It is suitable for ore bodies with a mining depth of 30 50m and an inclination angle of less than 5 10° External waste dump is the dump outside the open pit mine boundary for stacking

Get PriceThe crushing is a key operation in the coal mining semicontinuous process system which is different from the single bucket truck process The truck transports the coal required by the production to the designated crushing station for unloading and crushing

Get PriceBlasting is an essential part of it and it accounts for 15 20% of the total cost of open pit mining And the quality of blasting directly affects the efficiency of equipment such as mining transportation and coarse crushing and the total cost of the mine

Get PriceTough and reliable crushing and grinding equipment Designed to maximise performance and built for extra long service life our entire range of crushing and grinding equipment is backed by the Weir Minerals Service network operating in over 70 countries across the globe Find out more about our Enduron HPGR

Get PriceIn a conventional open pit mine or quarry primary crushing is often synonymous with a parade of loud dump trucks driving around generating dust noise and consuming excessive amounts of fuel A drill and blast team blasts the shot and develops a muck pile

Get PriceIndustrial background crusher rock stone crushing machine at open pit mining and processing plant for crushed View from above on the process of sorting coal mined Open pit mine Mining coal extractive industry anthracite Coal laden truck Open Pit Manganese Mining and Equipment Johannesburg South Africa April 20 2024 Open Pit

Get PriceIn Pit Crushing and Conveying IPCC Systems How we work with you How we work with you We can support you at every stage of the project lifecycle with a wide range of high quality products and services all backed by our expertise across sectors geographies and capabilities Maritime Design Consultancy

Get PriceOur wholly owned subsidiary Crushing Mining Services CSI provides world class tailored crushing screening and processing solutions for some of the world s largest mining companies We execute all stages of open pit mining including resource modelling mine planning drill and blast engineering load and haulage Read more Crushing

Get PriceThe Australian mineral sands mining groups are by nature progressive and adaptive to allow them to maximise mining production in ever changing and extensive surface ore bodies as well as minimising environmental impact and cost Traditionally mineral sands miners have used large fleets of scrapers in dry operations

Get PriceIn Pit Crushing IPC and Conveying project in 1985 The following paper describes the motivation for the project its design and development and finally operation 1 Direct operating costs includes all plant costs as well as the mine INTRODUCTION Palabora Mining Company operates an open pit mine in the north eastern corner of South Africa

Get PriceThe crushing system at the Martha Mine open pit consists of a combination of two types of crushers a jaw crusher and two Stamler feeder breakers The jaw crusher is capable of crushing material with a strength of over 150 megapascals MPa By way of comparison concrete has a strength of 20 30 MPa The Stamlers deal with the softer material

Get PriceDrilling in open pit mines High performance drilling is key to successful open pit mining with two principal areas of operation blasthole drilling and drilling presplit holes that help to enhance pit wall stability These operations have different requirements in terms of both their aim and the equipment used

Get PriceIn many operations the bottle neck is not the primary crusher but further downstream with the throughput being directly related to the PSD measured after the primary crusher For a complete mine to mill optimization measurements of fragmentation may be required at multiple locations to understand and optimize the overall process

Get PriceHighlights Open pit mine with run of mine ROM grade of grams per tonne gpt Au life of mine LOM On site crushing and sorting plant producing 700 tonnes per day tpd of mill

Get PricePF300 Essential part of IN PIT CRUSHING and CONVEYING IPCC The PF300 is a completely new fully mobile crushing plant with unique and compact design for on face mining applications which can be equipped with different Sandvik crusher types for any client s uniquely varied demands

Get PriceIn Pit Crushing The concept o f in pit crushing has been around for manyyears but in the current market with high energy and fuel cost labour shortages tire shortages and emission standards

Get PriceBlasting equipment is used for both underground and open pit mining operations and is known to be one of the most hazardous aspects of the job Designed to achieve maximum productivity and high reduction rate mining crushing equipment can come in a variety of different types for a range of jobs

Get PriceIn Pit Crushing and Conveying IPCC systems are receiving more attention today due to current characteristics of open pit mining operations and what is expected to occur in the future Today

Get PriceIn suitable mining projects in pit crushing and conveying IPCC can provide operating cost reductions to the tune of 20 60% savings depending on project specifics For this reason IPCC systems have been in use around the world for decades IPCC systems consist of a primary crusher installed in pit close to the active mining areas

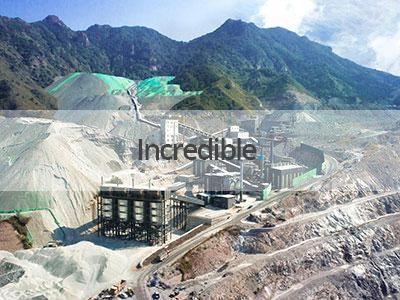

Get PriceIncredible has successfully built lots of crushing plants, grinding plants and metal ore dressing plants for our customers.

With over 30 years of experience, we become a renowned manufacturer in the stone crushing and mineral grinding industry. Headquartered in Shanghai, China, our expansive factory spans over 120 hectares, empowering us to cater to the production demands of global customers.