For the most up to date version of CFR Title 21 go to the Electronic Code of Federal Regulations eCFR Sec Iron elemental a Iron elemental CAS Reg No 7439 89 6 is metallic iron obtained by any of the following processes reduced iron electrolytic iron and carbonyl iron 1 Reduced iron is prepared by reacting ground

Get PriceCopper Powder Electrolytic Molybdenum Metal Chromium Metal Magnesium Aluminium Powder Applications of Metals Different types are Metals such as Nickel Cobalt Iron Chromium Manganese Aluminum etc provide properties of Anti Corrosion Ductability Hardness Malleability etc and is used in manufacturing of Welding Electrodes

Get PriceCN102134729A Method for preparing copper powder via electrolytic self desorption 07/26/2024 US7985326 Thermal and electrochemical process for metal production

Get PriceThe next stage in the production chain is the processing of bauxite into alumina or aluminium oxide Al 2 O 3 a white powder The most common process for making alumina from bauxite is the Bayer process which was first discovered over 100 years ago but is still in wide use today About 90% of alumina refineries in the world use the Bayer

Get PriceElectrolytic Iron High purity Iron Business Characteristcs and Applications Production Process of Electrolytic Iron Glossary Related Q A Let s try MAIRON SHP·UHP High purity Iron foil MAIRON SHP·UHP MAIRON Flake ATOMIRON Flake MAIRON Powder Environment and Recycling Business Building Materials—SOFT CALM Process of Creating

Get PriceIron powder is produced in many different grades for varieties of applications High purity fine iron powders are used to manufacture sintered components soft magnetic components brazing iron fortification friction products printing surface coating welding chemistry and polymer filtrations Iron powder products are classified by purity production method grain and density

Get PriceIron ore is commonly chemically reduced by carbon in a blast furnace at 1 600 °C to give liquid iron that is saturated with carbon and a mixture of CO 2 and carbon monoxide 3 The carbon

Get PriceIron / ˈ aɪ ər n / is a chemical element with symbol Fe from Latin ferrum and atomic number 26 It is a metal that belongs to the first transition series and group 8 of the periodic is by mass the most common element on Earth right in front of oxygen % and % respectively forming much of Earth s outer and inner is the fourth most common element in the

Get PriceWhite corundum The hardness of white corundum is slightly higher than that of brown corundum but the toughness is slightly worse It is easy to cut into the workpiece when grinding It has good self sharpness small heat generation strong grinding ability high efficiency and higher price than brown corundum Production Process Alumina powder → electrolytic smelting → crushing →

Get PriceDe Goey s view is that iron powder has a significant but well constrained role in energy storage transport and production that complements other zero carbon sources like hydrogen For a zero

Get PriceThe four main categories of fabrication are based on 1 mechanical comminution 2 chemical reactions 3 liquid metal atomization and 4 electrolytic deposition In addition to these major techniques several specialty techniques are used for special materials

Get PriceExotech s Chromium Powder is known for excellent uniformity in chemistry and size Powders are made in sizes from mm to <45 µm for pressing into solid targets Purities of Exotech powder are generally greater than % but are commonly % % and higher

Get PriceThe Hermite process t has attracted much attention as a method of making bleaching and disinfecting liquors from magnesium or sodium chloride solutions but it is not used for the production of free chlorine or caustic The Castner process l appears to be the most promising of the methods using mercury between the anode and cathode

Get PriceBased on type the global iron powder market is segmented into Reduced Iron Powder Atomized Iron Powder Electrolytic Iron Powder Detailed qualitative as well as quantitative type segment analysis will be provided in the report for 2024 to 2024

Get PriceCA1184883A CA000365540A CA365540A CA1184883A CA 1184883 A CA1184883 A CA 1184883A CA 000365540 A CA000365540 A CA 000365540A CA 365540 A CA365540 A CA 365540A CA 1184883 A CA1184883 A CA 1184883A Authority CA Canada Prior art keywords exchange membrane ion exchange group electrolytic cell anode Prior art date 1979 11 27 Legal status The legal status is an assumption and is not a legal conclusion

Get PriceThe chemical compositions of pure iron in this work typical technically pure iron and typical commercial electrolytic iron wt % Element Pure Iron in This Work Typical Technically Pure Iron Typical Commercial Electrolytic Iron C Si Mn P S

Get PriceThe production of powder metallurgy parts Many different metals are used to create powder metallurgy components including iron copper and steel powders Manufacturing process of iron and steel powders Powder production There are two common methods of powder production chemical and atomization

Get PriceSemantic Scholar extracted view of Electrochemical production of cobalt powder by using a modified hydrocyclone with ultrasonic assistance by O G Pérez et al have developed a method for continuous electrolytic production of iron cobalt powders with any desired new process has been developed for the

Get PriceAlmost all Earth Materials are used by humans for something The Electrolytic Cobalt Price manufacturers proovide Electrolytic Cobalt % Samarium Cobalt Titanium Anodes products with 1 These products can be used for different uses such as making machines making roads and buildings or making computer chips and concrete ceramics

Get PriceThe remaining mixture is a molten copper sulfide referred to as matte The next step in the refining process is to oxidize liquid matte in order to remove iron to burn off sulfide content as sulfur dioxide The result is 97 99% blister copper The term blister copper comes from the bubbles produced by sulfur dioxide on the surface of the copper

Get PriceElectrolytic Iron Powder is the purest iron powder in the world produced by Industrial Metal Powders I Pvt Ltd by the process electro deposition Electrolytic iron powder is the preferred iron for food diamond cutting tools pharmaceutical nutrition and other industrial applications where the importance of high purity raw material is emphasized

Get PriceThe first step in the overall powder metallurgy PM process is making metal powders There are four main processes used in powder production solid state reduction atomization electrolysis and chemical Solid State Reduction In solid state reduction selected ore is crushed typically mixed with carbon and passed through a continuous furnace

Get PriceElectrolytic Iron Powder % % Iron is produced through a complex electrochemical refining process ensuring uniform chemical composition and tight particle size distributions

Get PriceElectrolytic copper powder Copper Electrolitic powder Not reduced Process electrolysis of raw copper sieving Iron alloyed powder ready to press blends Pometon has developed products and process to mix the several elements of customised recipes and to guarantee appropriate quality of the supply Iron powder not Reduced

Get PriceZinc Production From Ore to Metal 80% of zinc mines are located underground 8% are of the open pit type with the remainder a combination of both In terms of production volume underground mines account for as much as 64% of overall zinc production combined underground/open pit mines provide 21% and the remaining 15% is sourced from open

Get Price3 The method is cost effective and the electrolytic iron powder manufacturer of India is making it possible to reach every staple food items 4 Under the fortification process the iron powder is added to the salt and edibles in such a small quantity that the characteristics taste feel and look of food items remain unchanged

Get Price2 Electrolytic Process Probably more has been written about the electrolytic process of producing metal powders than all other powder manufacturing processes This process is capable of producing a wide range of iron powders having globular nodular irregular or dendritic par ticles although the usual particle shape is dendritic

Get PriceElectrolytic iron powder is the most pure form of powder with 99% iron content which makes it suitable for numerous applications such as diamond cutting food additives pharmaceutical and

Get PriceA process for preparing iron powder suitable for use in preparing the iron potassium perchlorate heat powder fuel mixture used in thermal batteries comprises preparing a homogeneous dense iron oxide hydroxide precipitate by homogeneous precipitation from an aqueous mixture of a ferric salt formic or sulfuric acid ammonium hydroxide and urea as precipitating agent and then reducing the

Get PriceElectrolytic Iron Powder Electrolytic Iron Flakes Segmentation by application breakdown data from 2024 to 2024 in Section and forecast to 2024 in section Research Process and Data Source Economic Indicators Currency Considered IMP India Basic Information Electrolytic Iron Manufacturing Base Sales Area and

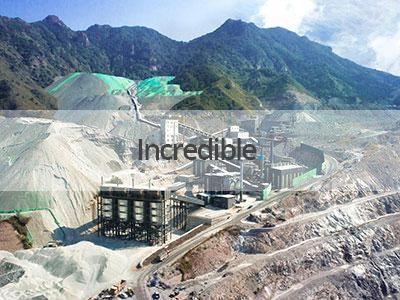

Get PriceIncredible has successfully built lots of crushing plants, grinding plants and metal ore dressing plants for our customers.

With over 30 years of experience, we become a renowned manufacturer in the stone crushing and mineral grinding industry. Headquartered in Shanghai, China, our expansive factory spans over 120 hectares, empowering us to cater to the production demands of global customers.