The physical simulation model the testing equipment enabled to induce the tension forces during the experimental measurements The tension force values TF = 4000 28 000 N were induced in the conveyor belt by means of a couple of the tensioning screws ID23 ID24 Fig filling rate A of the cross sectional area of the piped belt filled with the material was simulated by means of four

Get PriceCalculations for Screw conveyors Bechtel Calculations for screw conveyors Power in Kw P Q x L x K 3600 x 102 P = power in Kw Q = capacity in 1000 kg per hour L = conveyor screw length m K = friction coeffi cient P = v = speed in m per sec v = estring 395 T 49 0 212 64 50 94 0 info bechtel wuppertal Wuppertal F 49 0 212 64 50 94 10

Get PriceConveyor Dynamics Inc CDI has the experience and technology to evaluate the design of transfer chutes in material transport systems We use Rocky Discrete Element Modeling DEM software to evaluate and optimize conveyor transfer designs and when necessary we can couple DEM results with ANSYS to perform FEA and CFD analysis

Get PriceThe volumetric flow rate from the blower depends on the diameter of the pipe being used and the velocity required to convey the specified material For design purposes standard conditions 68°F psia 36% RH 3 4 are typically used in specifying the blower

Get PriceFlexible screw conveyors utilize an open helix shaft less auger design where the auger system can be bent along its length The outer tube of a flex auger is commonly extruded plastic tube or pipe The screw can be driven from either end The rate or volume transfer is determined by auger diameter and RPM Flex augers are normally

Get PriceKettle Reboiler Design This software tool is made to demonstrate the thermal design calculations and analysis of Kettle type software is user friendly and can be used to make preliminary sizing calculations that will help to give a clear outlook of the initial Category Applications Developer WeBBusterZ Engineering

Get PriceThe paper interprets the calculation of the size of force effects created by the reason of the effect of balled conveyor belt of pipe conveyor to the guide rollers located in the ring idler stations Knowing them is essential for the research of dynamic resistances by pipe conveyors operations Examined force effects were determined by the help of finite element methods

Get PriceA unique approach to load transport overhead conveyors leverage unused vertical space and save valuable floor space for other operations Sometimes referred to as hanging conveyors or overhead transport systems load handling with overhead conveyor systems takes place over work areas on continuous paths that can change direction horizontally and vertically

Get PricePipe steel outside diameter Ds mm Steel diameter shall be between 0 1500 Pipe steel wall thickness ts mm Wall thickness shall be between 0 50 Pipe internal corrosion allowance CA mm Corrosion allowance shall be between 15

Get PricePipe conveyors have been around for decades but one would be hard pressed to find any at hard rock mines The reason is simple lump size Pipe conveyors typically have a maximum diameter of 600 mm and as a rule the pipe s diameter should be at least four times the maximum lump size but drill and blast mining operations regularly create

Get Price16 01 2024· Wall thickness of a pipe is calculated using Pressure Temperature and materials This calculator makes the calculation using the equation below t = P d 2 c 2 S E − P 1 − Y Input Variables are as follows Design Pressure Maximum pressure at expected conditions Generally the maximum flange pressure at design

Get PriceSCREW CONVEYOR Design Speed Calculator Free download as PDF File pdf Text File txt or read online for free Pipe Heat Loss ingemarquintero Air Slide Version 24 Sept 03 Ahmed Mostafa AL Aboudy SAP Transactions Nalini Kanth Harshal Dhanawade

Get PriceUnderstanding a basic conveyor belt calculation will ensure your conveyor design is accurate and is not putting too many demands on your system Call Us Toll Free 1 800 451 4537 Menu Industries Automotive and Tire Building Materials Food General Industry Logistics and Warehouse Distribution Paper and Print

Get Priceconveyor deSign StepS Note If you need a conveyor designed/quoted you can simply fill out the spec sheet on send it to us and we will work through the design steps for you or you can do it yourself using the following steps 1 Establish conveying requirements see below 2 Identify the material and the corresponding material code

Get Priceratings of Standard Conveyor Components Using required horsepower from step 7 refer to pages H 26 and H 27 to check capacities of standard conveyor pipe shafts and coupling bolts STEP 9 Select Components Select basic components from Tables 1 8 1 9 and 1 10 in accordance with Component Group listed in Table 1 2 for the material to be conveyed

Get PriceAbout 7 000 000 metric tons are transported to two power plants using a 30 km long conveyor system The first 15 km conveyor—Yubei Section A—starts from the Yubei coal base and ends at the

Get PriceBelt lift off center and edge stresses belt buckling and lift off distances are calculated for each concave curve and every load case Likewise belt stresses in convex curves and required idler spacing is also calculated All cases are them summarized in an easy to read data table Users can quickly spot and correct problem areas

Get PriceI have used PneuCalc to help verify setup and trouble shoot various pneumatic conveying was quick and easy giving the guidance needed for each software will be another great tool for anyone that wants to understand the specifics of their pneumatic system air flow Thank you for all of your hard work lately I know

Get PriceBuy a wholesale screw conveyor calculation to facilitate convenient movement of materials at your workplace Industrial High quality BEST PRICE cassava screw chain auger conveyor screw conveyor design calculation sales / Set Sets Min Order CN Hebei Taizhe Machinery plastic round pipe air blower grain flexible screw conveyor

Get PriceFree Mechanical Design Engineering Calculators Online engineering analysis tools and data Motor Driving Conveyor Torque Force Calculator Motor Driving Speed Reducer Gear Belt or Chain Torque Force Calculator Pipe Shell Design Calculator Pressure Vessel

Get PriceThere are two main types of conveyor chain hollow bearing pin and solid bearing pin Hollow Bearing Pin Chain Hollow pin conveyor chain offers the facility for fixing attachments to the outer links using bolts through the hollow pin and attachment this method of fixing being suitable for use in most normal circumstances

Get PriceThe conveyor is powered by an electric motor through a V belt connection Tests were run on the conveyor using common granular materials like maize sorghum and gari at 13% moisture content The

Get PriceHelix DeltaT Conveyor Design Thank you for your interest in our bulk handling conveyor power calculation program To download a free copy and watch a one hour webinar on how to use the program please complete the registration form below 2024 The main parameters of the pipe conveyor is as 1 length 2 vertial lift 0m 3 load

Get PriceAugust 29 2024 Helix Technologies a Perth based engineering software developer has recently added a new pipe conveyor design feature into its Helix DeltaT6 Conveyor Design Software In a pipe conveyor the belt is formed into a circular tube that fully encloses the conveyed material The conveyor belt is an open trough under the loading

Get PriceThe general contractor Shandong Harbour Engineering awarded BEUMER Group with the installation of additional efficient pipe conveyors Project implementation took approximately eight months In only four months the system provider installed the mechanics of the systems with a total conveying length of approximately km and a conveying

Get PriceThe belt tension at steady state can be calculated as Tb = f L g [2 mi 2 mb mm cos δ ] H g mm …… Where Tb is in Newton f = Coefficient of friction L = Conveyor length in meters Conveyor length is approximately half of the total belt length g = Acceleration due to gravity = m/sec2 mi = Load due to the idlers in Kg/m

Get PriceDesign of shaft procedure One way is proposed in Figure 2 Shoulders are to be machined in the shaft to provide surfaces against which to seat the bearings and the gears on one side of each element The gears are restrained on the other side by retaining rings snapped into grooves in the shaft The bearings will be held in position by the

Get PriceThe three pertinent equations are T0 = Si Wb Wm for 3% sag T0 = Si Wb Wm for 2% sag T0 = Si Wb Wm for % sag In these equations Si is idler spacing in feet Wb is a weight per foot of the belt and Wm is a weight per foot of the material After calculating T 0 it is essential to add or subtract the weight of

Get PriceBelt Conveyor Capacity Table 1 Determine the surcharge angle of the material The surcharge angle on the average will be 5 degrees to 15 degrees less than the angle of repose ex 27° 12°= 15° 2 Determine the density of the material in pounds per cubic foot lb/ft3 3 Choose the idler shape 4 Select a suitable conveyor belt speed 5

Get PriceThe Conveyor Production Capacity calculator computes the number of units of some commodity that can be moved by a conveyor system in some amount of time

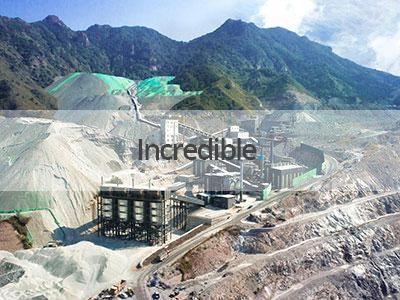

Get PriceIncredible has successfully built lots of crushing plants, grinding plants and metal ore dressing plants for our customers.

With over 30 years of experience, we become a renowned manufacturer in the stone crushing and mineral grinding industry. Headquartered in Shanghai, China, our expansive factory spans over 120 hectares, empowering us to cater to the production demands of global customers.