Froth flotation is a physicochemical process that separates particles based on differences in surface wettability Flotation takes place by passing finely dispersed air bubbles through an aqueous suspension of particles Fig 17 A chemical reagent called a frother is normally added to promote the formation of small bubbles

Get PriceSeveral methods are used to extract silver from different ores For maximum efficiency the method is geared to the nature of the ore If an ore contains gold and silver it is treated with a solution of sodium cyanide to dissolve both metals Most silver is extracted from ores with a froth flotation process which was discovered early

Get PriceThe flotation machine is mechanical equipment for realizing the froth flotation process and separating target minerals from ore At present nearly 2 billion tons of ore in the world are treated by the froth flotation process According to rough statistics about 90% of non ferrous minerals are recovered by the flotation method accounting for

Get Price19 A froth flotation process according to claim 1 wherein the at least one value mineral is selected from the group consisting of copper cobalt lead zinc nickel molybdenum gold silver and platinum group metals 20 A froth flotation process according to claim 19 wherein the platinum group metal is platinum or palladium

Get PriceFroth Floatation method Share with your friends Share 0 Dear Student Hydraulic washing It is based on gravity differences between the ore and the gangue particles biohydrometallurgy and several methods are used to recover copper zinc lead arsenic antimony nickel molybdenum gold silver and cobalt 0

Get PriceFlotation Cells ZJH minerals have more than 30 years history for producing flotation cells Our flotation cells are mainly used for the rough flotation scavenger and cleaning flotation of copper gold zinc lead barite fluorite graphite etc According to the client s requirement and drawings we could produce many kinds of flotation

Get PriceAt McClelland Laboratories our expertise crosses the breadth of metals and minerals from copper lead zinc gold and silver to chromites salts phosphates tungsten coal resins and iron ores We have studied flotation from feed material to by products and even waste streams Many of these have required the development of specific reagent

Get PriceIntroduction Froth flotation is one of the most broadly used separation methods in the mineral processing industry However despite being introduced in the early 1900s and numerous years of research and development flotation is still not fully understood and remains relatively inefficient

Get PriceLeaching is the process where a liquid substance extracts or dissolves minerals or other materials from a solid material Tank leaching is carried out in multiple tanks installed in series where the gold ore is mixed with a cyanide solution limestone and activated carbon and aerated with air bubbles Activated carbon is a very important

Get PriceFroth flotation is a very important mineral concentration process that is used to recover a vast array of different minerals containing molybdenum tungsten silver gold phosphate and potash In the flotation process ore is ground to a size sufficient to adequately liberate desired minerals from waste rock gangue it is conditioned as

Get PriceFroth flotation was used to recover silver bearing minerals using a combination of different collectors dithiophosphate dialkyl dithiophosphinates Aero 7518 Aero 7640 alkyl dithiophosphates

Get PriceDownload Citation Studies on Microwave Plasma Treatment of Froth Flotation Tailings An efficient technology is currently being searched for the processing of aged enrichment gold containing

Get PriceMinerals are recovered from ore by subjecting the ore in the form of an aqueous pulp to a froth flotation process in the presence of a collector of the formula R1 X R n N R2 2 Ia or R1 X R n N=Y Ib wherein R n is

The collectors such as pine oil eucalyptus oil and fatty acids enhance the non wettability of the mineral particles in froth floatation process Question 15 Name the substance used as depressant in the separation of two sulphide ores in froth floatation method CBSE Sample Paper 2024 Answer Sodium cyanide Question 16

Get PriceA flotation process is one method used throughout the industry to recover gold It s a very cost effective method for concentrating gold and is a desirable process used for the upgrading of low sulphide and refractory ore for further gold recovery treatment Froth flotation is a process used to selectively separate hydrophobic materials from

Get PriceFROTH FLOTATION RECENT TRENDS IIME JAMSHEDPUR 1998 pp 18 41 gold and silver also Some oxide minerals may be associated with sulphide minerals particularly in upper zone of a deposit FLOTATION PROCESS Flotation is a method of separating an ore species froth another based

Get PriceThe froth samples are taken off at 3 5 and 8 minutes The froth samples are dried overnight in an oven along with the flotation tailings The dried samples are weighed divided into suitable samples for analysis pulverized to insure suitable fineness and dissolved in acid for analysis

Get PriceMay 24 2022The froth flotation process is mainly used to separate non ferrous metals such as copper lead zinc nickel gold etc In addition froth flotation is suitable for the separation of fine particles that are difficult to recover by other beneficiation methods

Get PriceQuestion 15 Write the principles of the following methods i Froth floatation method ii Electrolytic refining Answer i Sulphide minerals become wet by oils whereas gangue particles by water ii Impure metal changes into ions which gain electrons at cathode to form pure metal whereas impurities are left as anode mud Question 16

Get PriceFroth Flotation Chemicals Market Scope of Report A recent study by on the froth flotation chemicals market offers a 10 year forecast from 2024 to 2024 The study analyzes crucial trends

Get Priceb Copper pyrite froth floatation process c Bauxite Leaching process a pyrolusite Magnetic separation process Answer b Copper pyrite froth floatation process Question 6 a Gold ore Cyanide leaching b Nickel ore Ammonia leaching c Aluminium ore Alkali leaching d Silver ore Acid leaching Answer

Get PriceIn most cases froth flotation method is used in the treatment of gold bearing ores with high reproducibility of sulfide minerals with good separation effect The froth flotation process can not only enrich maximum gold into the sulphide mineral concentrate but also discard the tailings so the processing cost is low

Get PriceA B S T R A C TBeneficiation of low grade gold and silver ores were investigated by gravity concentration flotation methods The ores were obtained from Way Kanan Region and Mount Burhan in

Get PriceThe froth carries the lighter ore particles along with it to the surface g The heavier impurities are left behind in water and these sink to the bottom Since the ore particles float with the froth at the surface this process is called froth floatation process h The froth is either skimmed off from the surface or transferred into another tank

Get PriceThe froth flotation chemicals market is expected to register a CAGR of over 3% during the forecast period Direct and reverse flotation are the two flotation methods depending on the

Get PriceA froth flotation process according to claim 1 or claim 10 wherein the at least one value mineral is selected from the group consisting of copper cobalt lead zinc nickel molybdenum gold silver and platinum group metals

Get PriceIntroduction to gold extraction methods Gold is extracted from the ores by MacArthur Forrest Cyanide process which utilizes the including zinc copper silver and iron Ore has to be mixed with mercury metal which combines with gold in the ore to form an amalgam Method of Extraction 1 Froth flotation process It is a process

Get PriceThese froths play a very important role in the froth flotation process It is because of these froths that the ore particles or ore powder can be attached to the sticky froth Then these froths carry the ore particles out of the slurry and reach the washing interface to remove the ore particles so as to achieve flotation process and obtain the

Get PriceIn this work different flotation preoxidation cyanidation methods are considered for treating a low grade refractory gold ore On the one hand the results of selective flotation show that 22% and % of total Sb and As respectively remained in the final tailings and only about 28% of the total Au remained for further cyanidation processes

Get PriceI claim 1 In a froth flotation process for beneficiating a gold silver or platinum group ore comprising slurrying liberation sized particles of said ore in an aqueous medium conditioning the resultant slurry with effective amounts of a frothing agent and a collector respectively and floating the desired gold silver or platinum group minerals by froth flotation methods the improvement

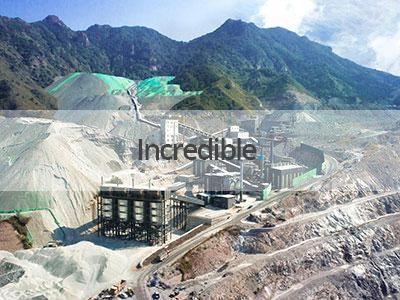

Get PriceIncredible has successfully built lots of crushing plants, grinding plants and metal ore dressing plants for our customers.

With over 30 years of experience, we become a renowned manufacturer in the stone crushing and mineral grinding industry. Headquartered in Shanghai, China, our expansive factory spans over 120 hectares, empowering us to cater to the production demands of global customers.