The pelleting process starts with a bin Figure 1 Item 1 in which the mixture of mash is stored From there the mash will flow by gravity into the pellet mill Figure 1 Item 2 This machine is usually located on the ground or main work floor level The hot extruded mash pellets flows by gravity into a cooler Figure

Get PriceStep #3 Drill Testing/Samples Next rock samples are taken through drill testing and analyzed Geologists and mining engineers use these samples to determine if gold actually exists the size of the deposit and the quality of gold in the ground beneath This information is used to determine if enough gold exists under the surface to make

Get PriceShredding is done to promote the melting process as small shredded metals have a large surface to volume ratio As a result they can be melted using comparatively less energy Normally aluminum is converted into small sheets and steel is changed into steel blocks 4 Melting

Get Pricegold extraction plants In the carbon in pulp process adsorption occurs after the leaching cascade section of the plant and in the carbon in leach process leaching and adsorption occur simultaneously In both processes the activated carbon is moved from one tank to another in countercurrent with the ore pulp until the recovery

Get PriceThe maximum gold recovery of % was obtained with the normal cyanidation process after 22 h whilst only 75 min was required with the Jetleach reactor to reach the same recovery After 120 min with the Jetleach reactor the gold recovery shows a further improvement of almost 2% and reaches a maximum of 98%

Get PriceElutriation is a process for separating a mixture ofminerals into two or more products and utilizes the difference in settling velocity between particles to effect this separation An upward flow ofwater runs countercurrent to the material flow in a hollow elutriation column

Get Price50TPH Diamond Extraction Process Flow chart South Africa diamond mining How processing plant configurated and what equipments were used 50TPH diamond processing flow PDF file Related machines Equipment name Model Qty set Bin / 1 Trommel scrubber 1200 4500 2024 11kw 2 Vibrating feeder 15TPH Barite Recovery Process Plant

Get PriceOrder a QF Gold and chronic hepatitis panel prior to starting baricitinib • Use of baricitinib with or following tocilizumab is discouraged due to risk of added immunosuppression and added risk of infection There are no data on sequential use of tocilizumab and baricitinib as it relates to safety and outcomes Tofacitinib

Get Priceprocesses The process is still widely used today because of its simplicity The Zadra process consists of circulating a 1% sodium hydroxide and % sodium cyanide water based solution upflow through a stationary bed of loaded carbon at a flow rate of about 2 bed volumes per hour at about 200 deg F Gold that was previously adsorbed on the

Get PriceThe common processes for recovery of gold solution includes i Carbon adsorption Merrill Crowe process iii electrowinning and iv ion exchange / solvent extraction Traditionally Merrill Crowe process was used to remove gold from a cyanide solution by using zinc dust to precipitate gold from its solution

Get Priceshred process and extract the constituent materials that can then be turned into new products This has to be performed within a 25 What is the Process Flow Sheet Diagram of the plant 26 What are the Market Opportunities for setting up the plant 27 What is the Market Study and Assessment for setting up the plant

Get Pricegold processing preparation of the ore for use in various products For thousands of years the word gold has connoted something of beauty or value These images are derived from two properties of gold its colour and its chemical stability The colour of gold is due to the electronic structure of the gold atom which absorbs electromagnetic radiation with wavelengths less than 5600 angstroms

Get PriceAbstract This paper reviews a series of alternative lixiviant systems for the recovery of gold from ores and concentrates For over 100 years cyanide has been the leach reagent of choice in gold

Get PriceFigure provides a flow diagram for a semi chemical pulp mill Of the chemical processes alkaline pulping the kraft or sulphite process is the most common and is shown in Figure PULP AND PAPER MILLS Chemical Processes Semi chemical Mechanical Total Kraft Sulphite Ontario 94 215 30 Quebec 10 8241 61

Get PriceFigure A schematic diagram of a complete liquid liquid extraction process from Separation Process Engineering by Wankat 2024 In the extraction process the feed which contains the first solvent or the diluent and the solute is sent to the extraction unit or the extractor Another solvent commonly called the solvent

Get PriceChemical precipitation adsorption with inorganic ion exchange sorbents solvent extraction and concentration with membrane technologies are the primary means of lithium recovery from brines Each lithium extraction and recovery process has unique advantages and challenges that need to be considered when determining the best fit for any project

Get PriceCHAPTER EIGHT Sulfur Recovery and Pollution Control Processes Pages 220 241 Select CHAPTER NINE Refinery Water Systems Book chapter Full text access Filled with handy process flow diagrams this volume is the only reference that a chemical engineer or process manager in a petroleum refinery needs for answers to everyday process

Get Price5 miscellaneous transfer storage and handling operations A generalized material flow diagram for a lime manufacturing plant is given in Figure 1 Note that some operations shown may not be performed in all plants The heart of a lime plant is the kiln The prevalent type of kiln is the rotary kiln accounting for

Get Price18R 97 Cost Estimate Classification System As Applied in EPC for the Process Industries 3/1/2024 PM01 PM06 X X 19R 97 Estimate Preparation Costs As Applied for the Process Industries 6/19/1998 PM06 X 20R 98 Project Code of Accounts 1/27/2024 PM06 PM05 PM07

Get PriceThe beneficiation process generates high volume waste called tailings the residue of an ore that remains after it has been milled and the desired metals have been extracted with cyanide gold or sulfuric acid copper If a mining project involves the extraction of a few hundred million metric tons of mineral ore then

Get PriceBased on the laboratory scale investigations of the selective leaching and combined ion exchange/solvent extraction method Ochsenkühn Petropoulou et al developed a pilot plant process for the recovery of scandium from red mud and the corresponding flow diagram is presented in Fig 8 The whole process consisted of four parts which were

Get Pricethe Benefits Coordination Recovery Center BCRC of the accident/incident/ illness The BCRC begins gathering initial information about the accident/ incident/illness The BCRC issues Rights and Responsibilities Letter If the beneficiary has an attorney or other representative they must submit appropriate proof of representation The BCRC

Get Pricegold which due to its low resistance will give up electrons to an oxidant or accept electrons from a reductant The ORP electrode will continue to accept or give up electrons until it develops a potential due to the build up charge which is equal to the ORP of the solution The typical accuracy of an ORP mea surement is ±5 mV

Get PriceLead and zinc ores are usually found together with gold and silver A lead zinc ore may also contain lead sulfide zinc sulfide iron sulfide iron carbonate and quartz When zinc and lead sulfides are present in profitable amounts they are regarded as ore minerals The remaining rock and minerals are called gangue Forms of Lead and Zinc Ore

Get PriceThe 5 Lifecycle Stages of Mining 1 Exploration Prospecting Stage This is the first and most essential step of the mining process in order to open a mine companies must first find an economically sufficient amount of the deposit an amount of ore or mineral that makes exploitation worthwhile Geologists are enlisted by the companies to

Get PriceMedicare s recovery case runs from the date of incident through the date of settlement/judgment/award where an incident involves exposure to or ingestion of a substance over time the date of incident is the date of first exposure/ingestion Within 65 days of the issuance of the RAR Letter the BCRC will send the CPL and Payment

Get PriceSluice design can lead to higher gold recovery if the force of the water traveling through the sluice is decreased A series of rifles can help break the flow to improve recovery A zig zag sluice also achieves this by creating a drop between the first and second platform that disrupts the velocity of the water as it travels down the sluice

Get PriceHeap leaching is an industrial mining process used to extract precious metals copper uranium and other compounds from ore using a series of chemical reactions that absorb specific minerals and re separate them after their division from other earth materials Similar to in situ mining heap leach mining differs in that it places ore on a liner then adds the chemicals via drip systems to the

Get PriceThe process of thiosulfate leaching of gold were researched by employing the response surface methodology RSM The block flow diagram process steps of this study is shown in Physicochem Probl Miner Process 55 2 2024 537 551539 Fig 2

Get Pricecontributed to the formation of kerogen see Chapter 6 This process began millions of years ago when small marine organisms abounded in the seas As marine life died it settled at the sea bottom and became buried in layers of clay silt and sand The gradual decay by the effect of heat and pressure resulted in the formation of hundreds of

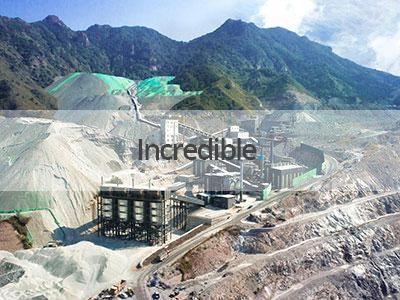

Get PriceIncredible has successfully built lots of crushing plants, grinding plants and metal ore dressing plants for our customers.

With over 30 years of experience, we become a renowned manufacturer in the stone crushing and mineral grinding industry. Headquartered in Shanghai, China, our expansive factory spans over 120 hectares, empowering us to cater to the production demands of global customers.