Calculate the reduction ratio by dividing output torque by input torque If 50 foot pounds on the output results from 10 foot pounds on the input the reduction ratio is 5 to 1 This is similar to counting gear teeth In that case a 42 tooth gear driven by a 14 tooth gear calculates to 42/14 or a 3 to 1 reduction ratio

Get PriceLorem ipsum dolor Address Science Kexue Avenue Tel 0086 371 86162511 Email [email protected]

Get PriceROLL CRUSHER Roll crushers are used for producing additional reductions in the sizes of stone after the output of a quarry has been subjected to one or more stages of prior crushing Roll crushers have a theoretical MAXIMUM reduction ratio of 4 1 If a 2 inch particle is fed to the roll crusher the absolute smallest size one could expect from

Get PriceCalculate Hammer Crusher Impact Force Pdf Khira Crush grizzly screen prior to crushing to remove material finer than the closedside setting Setting jaw crushers Ideally the reduction ratio of a jaw crusher should be 6to1 There are different ways to calculate reduction ratio but the best way is something called the P80 factor

Get PriceFirst improve the crushing chamber Through the analysis of crushing chamber of jaw crusher we got to know that curved cavity can reduce material clogging Using stepped structure with high crushing cavity and small mesh angle we can increase crushing ratio avoid wear and tear of equipment reduce the lining board wear consumption

Get PriceQJ241 JAW CRUSHER ENGINEERING IN MOTION QJ241 JAW CRUSHER KEY SPECIFICATIONS DATA Equipment Single toggle C10 jaw crusher Feed opening 1000 mm x 650 mm / 40 x 26 Optimum feed size 520 mm3 / 21 inch3 Engine Acert 168 kW / 225 hp Transport dimensions m / 45 7 ⅜ l m / 8 7 ⅞ w m / 10 6 ⅝ h

Get PriceSetting jaw crushers ideally the reduction ratio ofaw crusher should be 6to1 there are different ways to calculate reduction ratio but the best way is something called the p80 factor the reduction ratio is then calculated by comparing the input feed size passing 80 percent versus the discharge size that passes 80 percent

Get PriceSetting jaw crushers Ideally the reduction ratio of a jaw crusher should be 6 to 1 There are different ways to calculate reduction ratio but the best way is something called the P80 factor How To Adjust Jaw Crusher Gap

Get Pricecrushers mass balance GM stone crusher machine is designed to achieve maximum productivity and high reduction ratio From large primary jaw crusher and impact … Cement Kiln Heat And Mass Balance Pure Line Heat Balance For Cement Mill jaw crusher heat balance Balance Crusher Mass energy balance of crusher energy balance for an crusher

Get Priceto ball filling variation in the mill The results obtained from this work show the ball filling percentage variation is between % which is lower than mill ball filling percentage according to the designed conditions 15% In addition acquired load samplings result for mill ball filling was %

Get PriceAdditionally jaw crusher feed should be pre screened using a grizzly screen prior to crushing to remove material finer than the closed side setting Setting jaw crushers Ideally the reduction ratio of a jaw crusher should be 6 to 1 There are different ways to calculate reduction ratio but the best way is something called the P80

Get PriceFor a given ratio of reduction the type of crusher with a flared crushing chamber will usually deliver a cleaner product than any of the older types conversely more reduction can be performed in the machine without creating excessive fines The facts outlined in the foregoing paragraph have an important bearing on crushing plant design

Get PriceTECHNICAL NOTES 5 CRUSHERS learn more The capacity of the crusher is determined by its size The gape determines the maximum size of material that can be accepted Maximum size that can be accepted into the crusher is approximately 80% of the gape Jaw crushers are operated to produce a size reduction ratio between 4 1 and 9 1 Gyratory crushers

Get PriceDec 8 2021Calculating the Width of Crusher when the Jaw Crusher Rating and the Gape Size is Given W = Jr / G Where W = Width of Crusher J r = Jaw Crusher Rating G = Gape Size Let s solve an example Find the width of crusher when the jaw crusher rating is 40 and the gape size is 4 This implies that

Get PriceThe BOYD Crusher is the world s first double acting fine jaw crusher Its patented design includes top and bottom driven moving jaws enabling the maximum amount of crushing in a single pass The Big BOYD Crusher takes lump sizes of up to 150mm pieces and crushes them to 10mm or less in a single pass reducing time for every sample

Get PriceThe crusher consumes 40 kw of power of which 5 kw are required for running the mill empty calculate the power consumption if 12 tonnesh of this product is further crushed to 5 x 10 4 m size in the same mill assume that rittingerslaw is applicable •it is desired to crush 10 tonhr of iron ore hematite the size of the feed is

Get PriceHow To Calculate Gyratory Crusher Speed Samac How To Calculate Gyratory Crusher Speed •Gyratory •Cone Crusher Standard Head Short Head •Roll Crusher the faster the speed of the crusher the finer Crushing 101 Calculating Reduction Ratio Live a Chat Simplification of Jaw crusher for Artisanal Aggregates Miners

Get PriceYou have tried different impactors and wear and the amount of fines are a challange To get your job done you now require multiple machines that are costly and complex Other Mobile Impact Crusher Models RUBBLE MASTER offers a wide range of mobile impact crushers ranging from 90 385 TPH RM 100GO RM 90GO

Get PriceElectrical energy consumption of a crusher plant pdf crusher machine shenbang stone crushing equipment is designed to achieve maximum productivity and high reduction ratio jaw crusher power calculation from energy meter reading to study the working characteristics of a jaw crusher calculate the energy consumption as Details

Get PriceThe capacity of the crusher is determined by its size The gape determines the maximum size of material that can be accepted Maximum size that can be accepted into the crusher is approximately 80% of the gape Jaw crushers are operated to produce a size reduction ratio between 4 1 and 9 1 Gyratory crushers

Get PriceMARINE ENGINEERING BUNKER CALCULATION Aug 11 2024 0183 32 the volume of ullage is 105529m 3 this is observed volume take the temperature of the tank the temperature is 48 176 c as the bunker delivery note the density of the bunker is 988kg/ m 3at 15 176 c from the volume correction table we can find out the correction factor for the oil for 988kg/m 3 density is

Get PriceHow To Calculate Efficiency Of Jaw Crusher GM stone crusher machine is designed to achieve maximum productivity and high reduction ratio From large primary jaw crusher and impact crusher to cone crusher and VSI series for secondary or tertiary stone crushing GM can supply the right crusher as well as complete crushing plant to meet your

Get PriceThis form works out volume of one motion of the jaw multiplies by RPM then multiplies again by 60 to give volume/hour This looks better but it still doesn t work Example Metso C80 jaw crusher 2″ CSS Q = cot 10° 350 60 = 111 m³/h I have to guess the throw the catalogue doesn t say

Get PriceIn stone crushing the ratio of the maximum dimension of stone Explanation of reduction ratio how to calculate jaw crusher reduction ratio Crushing Rule of Thumb Mineral Processing Extractive Metallurgy Dec 16 2024 Above 725 tonnes/hour jaw crushers cannot compete with gyratory for high reduction ratios up to 40 1 but are rarely

Get PriceSep 19 2024 0183 32 Jaw crushers offer reduction ratios of up to about 6 1 while cone crushers can reduce material size up to a maximum of 8 1 ratio The finer the crushing the smaller the reduction ratio As a basic rule jaw crushers are the primary crusher taking the mined aggregate and reducing it to a size that a cone crusher

Get PriceJaw crushers are operated to produce a size reduction ratio between 4 1 and 9 1 Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3 1 to 10 1 The primary operating variable available on a crusher is the set and on jaw and gyratory the open side set OSS is specified This reflects the fact that considerable

Get PriceThe impact crusher size reduction ratio is 20 to 1 The vertical shaft impact crusher size reduction ratio is 4 8 to 1 The vertical roller mill size reduction ratio is to 1 The hammer crusher size reduction ratio is 20 to 1 Pre Article Crusher Plays An Important Role In Artificial Sand Production Line Contact

Get PriceThis cannot be calculated from motor side 5 Having decided the load torque you can decide the required power at motor shaft available motor size gear ratio and so on Calculation Jaw Crusher 11 Aug 2024 Crushers Crushing Ratio Is Ratio Of Raw Reduction Ratio Calculation Jaw Crusher Sheet Jaw Crusher How To Calculate Jaw Crusher Reduction

Get PriceDuring comparatively slower jaw movements and frequency Rose and English derived the capacity QS as where LT = throw ν= frequency cycle/min W = width of jaw plates m LMIN = closed set R = machine reduction ratio gape/set and QS = capacity slow frequency in terms of volume of material product per hour

Get PriceFormula To Calculate Reduction Ratio On A Rock Crusher Calculate The Reduction Ratio And The Number Of Milling Apr 16 it calculated by multiplying reduction ratios of all the stages see formula below rrrr1rr2rrn n number of milling stages rrp reduction ratio of the p stage source formulaminerallurgy for example in a crushing circuit that

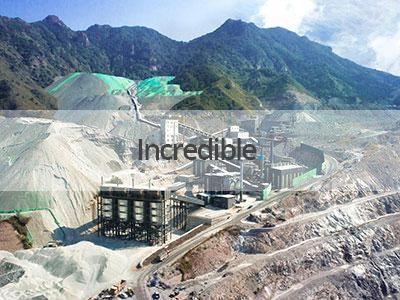

Get PriceIncredible has successfully built lots of crushing plants, grinding plants and metal ore dressing plants for our customers.

With over 30 years of experience, we become a renowned manufacturer in the stone crushing and mineral grinding industry. Headquartered in Shanghai, China, our expansive factory spans over 120 hectares, empowering us to cater to the production demands of global customers.