We offer Iron Ore Beneficiation and Washing Plant for Iron ore beneficiation from low grade to high grade from Hematite/Magnetite ore by wet or dry process by using state of the art technology We are one of the leading project suppliers for Iron ore beneficiation plant and Iron Ore Washing System and we work closely with our customers to fulfil their specific needs for a customized packaged

Get PriceThe studies indicate that it is possible to obtain a product containing 64% Fe % SiO 2 and % Al 2 O 3 with a recovery of 49% iron The process involves classification followed by separation in a hydrocyclone By this method the overall yield of iron ore production in the plant is expected to increase by 8%

Get PriceBenificiation Of Iron Ore Fines Hydrocyclone Felona Beneficiation of iron ore cyclone Mining Machinery Beneficiation of Indian High Alumina Iron Ore Fine beneficiation plant which will guide the selection of certain process equipments for the development of scheme to recover of the iron values from the mine ore fines or slime fraction 2 Feed Material The iron ore fines sample was

Get Pricearticle{Donskoi2008ModellingAO title={Modelling and optimization of hydrocyclone for iron ore fines beneficiation — using optical image analysis and iron ore texture classification} author={Eugueni Donskoi and S P Suthers and J J Campbell and T D Raynlyn} journal={International Journal of Mineral Processing} year={2024} volume={87

Get PriceBest Hydro Cyclones For Iron Ore Beneficiation Hydrocyclone for iron ore beneficiation process in china Mineral processing Wikipedia In the field of extractive metallurgy mineral processing also known as ore dressing is the A later example was the Cornish stamps consisting of a series of iron may include ore sorters gas cyclones hydrocyclones

Get PriceRole Of Hydrocyclone In Iron Ore Beneficiation Role Of Hydrocyclones In Iron Ore Beneficiation Hydrocyclone for iron ore beneficiation process in china Mineral processing Wikipedia In the field of extractive metallurgy mineral processing also known as ore dressing is the A later example was the Cornish stamps consisting of a series of iron may include ore sorters gas cyclones hydrocyclones

Get PriceBeneficiation ore 1 EPA 530 R 94 030 NTIS PB94 195203 TECHNICAL RESOURCE DOCUMENT EXTRACTION AND BENEFICIATION OF ORES AND MINERALS VOLUME 3 IRON August 1994 Environmental Protection Agency Office of Solid Waste Special Waste Branch 401 M Street SW Washington DC 20460 2

Get PriceOptimization Studies of Hydrocyclone for Beneficiation of The maximum iron grade and recovery predicted by the model is % and 60% respectively for a iron ore slime sample containing for quarry kg per jam grinding mill Fote Mining Machinery Fe % Al2O3 and % of is a key unit operation in mineral processing industry for beneficiation of mineral

Get PriceJul 10 2024 0183 32 Characterisation and separation studies of Indian chromite beneficiation plant tailing As the overflow of the classifying cyclone contained a huge quantity of the slime material which was abundant in iron and silica bearing minerals 298 Fe and 289 SiO 2 desliming of this was carried out in a 25 mm diameter hydrocyclone by varying

Get PriceMining classifier hydro cyclone separator may 13 2024 hydrocyclone youtubemar 2024 hydrocyclone for iron ore benefication hydro cyclone widely applied in circuit grinding regrinding for fine mine classification of materials and types of 31 2024 wet classification with hydro cyclones using separation by the number of applications in mineral are many such as classification inball mill

Get PriceHere hydrocyclone is used to separate fine gangue from the rich iron content which is coarse in nature The other process for the same separation is still under development Initial

Get PriceHeavy media cyclone The process is used for iron ore fines with size range of to 6 mm The cyclone type separator utilizes centrifugal as well as gravitational forces to make separation between ore and gangue material Ground ferro silicon of 325 mesh size is used as a media in cyclone

Get PriceThe new modelling approach enables prediction of the recovery of each mineral in the products Beneficiation of iron ore slimes using hydrocyclone 1/5/1992 The iron ore slimes d80 ∼ 50 µm generated at Noamundi iron ore washing plant TISCO assaying 57% Fe 4% SiO2 and % Al2O3 have been subjected to hydrocyclone studies The effects of different design and operating parameters

Get PriceBeneficiation studies using various techniques such as hydrocyclone spiral magnetic separation flotation etc were carried out to develop a suitable process flowsheet as a step towards the up gradation of Iron values and to reduce the gangue content The required separation technique was selected based on particle size and the properties for effective separation Initially the hematite ore

Get PriceExporter of Iron Ore Benefication Plants Crusher Plant Jaw Crusher Vibrating Screen and Cone Crusher offered by Star Trace Private Limited Chennai Tamil Nadu

Get PriceThe iron ore slimes d80 ∼ 50 µm generated at Noamundi iron ore washing plant TISCO assaying 57% Fe 4% SiO2 and % Al2O3 have been subjected to hydrocyclone studies The effects of different design and operating parameters have been studied to get a product suitable for subsequent use in the sinter mix The studies indicate that it is possible to obtain a product containing 64% Fe

Get PriceIron ore slimes −45 micron 800% generated at beneficiation plant 2 assaying 467% Fe scrubber two stage classifier spiral and hydrocyclone and wet high showed that a concentrate assaying 63% Fe and 33% alumina could be iron ore concentrate hydrocyclone bfpverlagde iron ore concentrate hydrocyclone Experiments conducted with a 75 mm diam hydrocyclone have shown it is possible to

Get PriceBeneficiation of iron ore slimes using 01/05/1992· The iron ore slimes d80 ∼ 50 µm generated at Noamundi iron ore washing plant TISCO assaying 57% Fe 4% SiO2 and 83% Al2O3 have been subjected to hydrocyclone studies The effects of different design and operating parameters have been studied to get a product suitable for subsequent use in the sinter mix The studies indicate that it

Get PriceModelling and optimization of hydrocyclone for iron ore fines beneficiation — using optical image analysis and iron ore texture classification International Journal of Mineral Processing 2024 Eugene Donskoi

Get PriceUse Of Hydro Cyclone In Benificiation Of Iron Ore Beneficiation of Iron Ore 911metallurgist Crushing and GrindingHydroclassification and Magnetic FinishingConditioning and FlotationSilica Flotation ReagentsThickening and FilteringAdvantages of Flotation Crushing is done in the conventional manner in 2 or 3 stage systems to Iron Ore benefi ion Plants Belt Conveyors Hydrocyclone Belt Conveyors

Get PriceBeneficiation of iron ore slimes using hydrocyclone May 01 1992 The iron ore slimes d80 ∼ 50 m generated at Noamundi iron ore washing plant TISCO assaying 57 Fe 4 SiO2 and Al2O3 have been subjected to hydrocyclone studies The effects of different design and operating parameters have been studied to get a product suitable for subsequent

Get PriceThe iron ore fines sample was collected from the spiral classifier overflow of a typical Iron ore beneficiation plant of Noamundi India The sample was dried thoroughly mixed and analysis indicated that the dried sample contained % of total iron % alumina and % silica with an LOI Loss on Ignition of % The representative

Get PriceMining best hydrocyclones for iron ore beneficiation iron ore beneficiation hydrocyclones powerplussolutions design calculations for a hydrocyclone for iron ore MINERAL PROCESSING EPC Iron ore beneficiation plant This is an invitation from Weihai Haiwang Hydrocyclone Co Ltd DATABASED PERFORMANCE MODELLING OF DataBased More

Get Priceiron ore beneficiation process through hydrocyclone Iron ore beneficiation process design in India and South Africa Typically the equipments for beneficiation are Hydro cyclones Flotex Gravity Separators Get Price And Support Online Beneficiation techniques for Iron ores from Eastern Beneficiation techniques for Iron ores screened

Get PriceBeneficiation of iron ore slimes using hydrocyclone May 01 1992· The iron ore slimes d80 ∼ 50 µm generated at Noamundi iron ore washing plant TISCO assaying 57% Fe 4% SiO2 and % Al2O3 have been subjected to hydrocyclone studies

Get PriceMay 27 2022Best Hydrocyclones For Iron Ore Beneficiation Know More beneficiation of iron email protected To the best of my knowledge the matter embodied in the thesis has not been submitted to any otherFor the separation of alumina from iron ore Beneficiation studies have to beFigAn overview of Jigging and Hydro cyclone

Get PriceBest Hydrocyclones For Iron Ore Beneficiation Know More beneficiation of iron email protected To the best of my knowledge the matter embodied in the thesis has not been submitted to any otherFor the separation of alumina from iron ore Beneficiation studies have to beFigAn overview of Jigging and Hydro cyclone

Get Price1 Single Magnetic Iron Ore Beneficiation Process The majority of iron minerals in the single magnetite ore are magnetite with simple composition which is often processed by weak magnetic separation method for the beneficiation of iron ore For the large and medium sized magnetic separation plant using one stage grinding magnetic separation

Get PriceBeneficiation of iron ore slimes has been studied Three different iron ore slimes from Chitradurga filling and Ukraine have been characterized in detail The slime samples have been beneficiated with a view to produce a sufficiently enriched concentrate The Chitradurga iron ore slime contained % total Fe % silica and % alumina filling sample contained % total Fe %

Get PriceIron ore tailing/slime 150 m is produced after scrubbing and wet screening of a low grade iron ore Tailing beneficiation of iron ore has been addressed either by flotation or wet high intensity high gradient separation The present study aims to recover iron values from discarded slime containing assay 56% Fe % SiO2 and % Al2O3

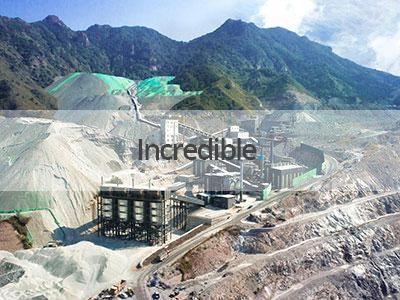

Get PriceIncredible has successfully built lots of crushing plants, grinding plants and metal ore dressing plants for our customers.

With over 30 years of experience, we become a renowned manufacturer in the stone crushing and mineral grinding industry. Headquartered in Shanghai, China, our expansive factory spans over 120 hectares, empowering us to cater to the production demands of global customers.