The laterite ore is mined by removing the overburden and limonitic layer free moisture in the mined ore is reduced from 32% to 20% in rotary dryers and nickel is recovered as nickel matte using a conventional Reduction Kiln and Electric Furnace RK EF process Fig 1

Get PriceChina Hanking Holdings has signed an agreement to acquire a 70% interest in Northeastern Lion in a deal valued at $50m The acquisition supports China Hanking s long term strategy to diversify mining resources and expand into international markets Northeastern Lion owns laterite nickel mines in Indonesia through three project

Get Pricep 2 Impacts of Laterite Mining of Nickel and Iron Ores on Watersheds PREMISE Open pit contour or strip mining of laterites involves removing 1 to 2 meters of topsoil to be able to extract the laterite limonite and saprolite deposits which occupy the soil strata from 3 to 25 meters below the ground

Get PricePrior to starting equipment design Kamengo conducted material flow testing using a sample of the dewatered nickel laterite The testing includes a series of bench scale tests that are used to derive the minimum geometry angle of sloping walls sloping wall material discharge opening required to reliably discharge a bulk solid

Get PriceThe high demand for nickel based materials globally and the availability of nickel laterite ore in Indonesia make laterite nickel mining in Indonesia inevitable Analysis and Control for Heavy Equipment Spare Parts Inventory in the Nickel Mining Industry IPTEK Journal of Proceedings Series / 2024 Vol

Get PriceLaterite Crushing Process Laterite Mining Machinery TY Crusher Typically laterite ore crushing machine refers to the crushing equipment used in the crushing process of laterite bearing rocks Nowadays in the laterite mining industry impact crusher is widely used as the laterite crushing machine Calcination Equipment

Get PriceIn the last five years the annual average number of drill holes carried out was 182 by which LARCO covered an area of 1 200 000 m2 annually Based on our data nickel laterite mineral resources exceed 250 million tonnes and are mainly spread over three large areas of Greece Central Euboea Neo Kokkino area and the county of Viotia

Get PriceNickel laterites on the other hand are found nearer or at the surface and are generally classified as limonitic the upper layer based on nickeliferous limonite Fe Ni O OH or saprolitic the

Get PriceLaterite Nickel Ore Rotary Kiln Type kiln equipment Capacity 42t/h Application field Large laterite nickel ore roasting reduction rotary kiln is one of the key equipment of the laterite kiln smelting ore dried into laterite kiln kiln heated to 800 celsius after the removal of water surface of ore and water of crystallization and iron nickel and cobalt oxide reduction in

Get PriceJul 06 2024 The Expresswire Nickel Mining Market Insights 2024 By Types Pentlandite Sulfide Ore Laterite Nickel Ore Applications

Get PriceTherefore the comprehensive utilization value of the mine is very high For the processing of the mine calcining equipment is generally used The main calcining equipment at this stage is rotary kiln the laterite nickel rotary kiln requires an advanced technology and is easy to operate

Get PriceThe laterite ore is usually obtained via open cut mining methods Open cut mining is a form of surface mining where the ore is extracted from an open air pit whereas the sulfide ore which is usually found combined with copper is mined underground Equipment used for laterite ore mining include big shovels draglines and front end loaders

Get PricePerformance of Laterite Cement Blocks as Walling Units in … Placer Gold Processing Plant Mobile Placer Ore Processing Plants are particularly versatile… cement manufacturing process with laterite Grinding Mill … For a laterite cement mixture of 45% sand and 5% cement a compressive strength of N/mm 2 …

Get PriceNickel Plate Express uses a 1956 F9 diesel locomotive originally built for the Erie Mining Company 4214 provides the main locomotive power for all Nickel Plate Express excursions The locomotive boasts a silver black and yellow collaborative Nickel Plate schemeWe import foreign laterite nickel ore resources to produce highquality nickel alloy

Get PriceDrawing on developments discussed at the successful InternationalLaterite Symposium held in 1979 these proceedings from the 2004symposium will provide updates on certain projects and developmentsdiscussed in 1979 as well as cover developments in the interimperiod in

Get PriceMAKING OF LEASE PURCHASE OPTION OF HEAVY EQUIPMENT AT NICKEL LATERITIC ORE MINING Rini Novrianti Sutardjo Tui Aryanti Virtanti Anas and Nur Fitriani Department of Mining Engineering Engineering Faculty Universitas Hasanudd in Makassar Indonesia analysis it was indicated that laterite nickel ore production in 2024 2024 wou ld still be

Get PriceNickel is a chemical element with symbol Ni and atomic number 28 It is a silvery white lustrous metal with a slight golden tinge Nickel is a hard and ductile transition nickel powdered to maximize reactive surface area shows a significant chemical activity but larger pieces are slow to react with air under standard conditions because an oxide layer forms on the surface and

Get PriceMining Solution Related Equipment Jaw Crusher … of wet and/or dry screening are used in beneficiation of an oxide nickel ore nickel ore beneficiation equipment nickel ore beneficiation … Crushing process nickel ore beneficiation begins with the milling of extracted ore in … separating the water from the heavier mineral rich solids

Get PriceNickel laterite deposits in the Sorowako and Petea area are generally classified into two main types West Block and East Block types depending upon the nature of bedrock the level of serpentinisation ease of mining size of boulders degree of fracturing of the bedrock optimum screen fraction that carries nickel grades and the silica to magnesia ratios in the mineralisation

Get PriceWhen limonitic laterites roasted at temperature of 600 °C for 2 h with sulfuric acid/laterite ratio of 1/4 mL/g a total of % of scandium and only % of iron were extracted into

Get PriceScheduled to start in September 2024 the mine will produce 45 000 tpa of nickel and 2 800 tpa of cobalt over a commercial life of 40 years CVRD has been developing this project for five years and has chosen HPAL technology to process the nickel laterites An Australian pilot plant has produced LME grade nickel cathode at an average leaching

Get PriceOct 24 2021Nickel laterite ore is used to produce nickel metal predominantly to manufacture stainless steel as well as nickel sulfate a key ingredient in the batteries that drive electric vehicles Nickel laterite production is on the rise and surpassing conventional sulfide deposits

Get Price1 Mineral Engineering Technical Services PO Box 5778 St Georges Tce WA 6831 P 61 8 9421 9000 F 61 8 9325 8311 ABN 66 009 357 171 W E info A division of Midas Engineering Group Nickel Ore Processing Trends The Rise of Nickel Laterites and Advances in Sulphide Processing

Get PriceOct 6 2020According to an ASX announcement on 8 October 2024 by Highland Pacific a minority partner in the Ramu Nickel JV a US$ billion expansion is being investigated Ramu is currently rated at

Get PriceThe laterite nickel ore is rich in resources accounting for about 70% of the world s continental nickel resources and the exploration cost is low Nickel laterite is usually mined by open pit mining methods This means that mining costs are low The processing method of laterite nickel ore has gradually matured

Get PriceIn the blog about The value of mineralogical monitoring we discussed the importance of mineralogical monitoring for efficient ore beneficiation on the examples of copper and nickel ores This blog elaborates on the nickel ore application in more detail Nickel ore processing Primary sources of mined nickel are [1] magmatic sulphide deposits with pentlandite as a main ore mineral and [2

Get PriceAt present the beneficiation methods of laterite nickel ore include nickel sulfur process rotary kiln submerged arc furnace process RKEF sintering blast furnace reduction process direct

Get PriceThe limonitic nickel laterite ore is beneficiated by the selective reduction roastingmagnetic separation process Separation Nickel Ore Nickel Ore Process Nickel Ore Mining Equipment Xinhai Nickel Ore can be divided into copper sulfide nickel ore and nickel oxide ore flotation is the main beneficiation method when processing copper sulfide

Get PriceA shallow surface mining program was originally selected as the mining method due to the nickel laterite ore being located near the land surface This method incorporates benching and terracing of housing the analytical equipment including the X ray Fluorescence Spectrometer and the Atomic Absorption Spectrometer Employee Camp

Get PriceNickel deposits are generally found in two forms sulphide or laterite About 60% of the world s known nickel resources are laterites The remaining 40% are sulphide deposits Nickel Sulphide Deposits the principal ore mineral is pentlandite Fe Ni O OH are formed from the precipitation of nickel minerals by hydrothermal fluids

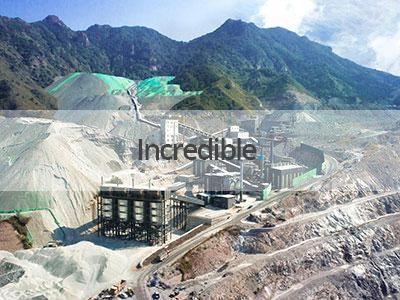

Get PriceIncredible has successfully built lots of crushing plants, grinding plants and metal ore dressing plants for our customers.

With over 30 years of experience, we become a renowned manufacturer in the stone crushing and mineral grinding industry. Headquartered in Shanghai, China, our expansive factory spans over 120 hectares, empowering us to cater to the production demands of global customers.