Coal Hadling Systems For transferring coal from trucks wagon tippler hopper through bucket elevators/ belt conveyors to boiler bunkers Packaging Coveryor System High Performance Packaging in High Performance Jignesh Engineering Company Since 1993 India Leading Manufacturer of Coveyor Systems and Material Handling Machines

Get PriceCoal Conveyor Fire Protection 04 February 2024 Issue EU1 Page 1 Fire protection guidelines for Conveyors transporting coal Conveyor systems in general have a fire risk due to external events and equipment materials The wave length spectrum and intensity of this IR depends on the material s temperature and for solid

Get PriceBEUMER Group provides engineering of stockpiles for the coal industry Hard coal is temporarily stored in stockpiles and then continuously fed to be processed as needed The design of the depositories must ensure constant filling and reliable emptying When reclaiming from the side scraper chains move the material on a belt conveyor

Get PriceCoal Handling Plants Material Handling Conveyor Bag Filters Conveyor System Industrial Conveyors Conveyor Accessories Slat Conveyors Screw Conveyor Redler Chain Conveyor Crushing Equipment Bucket Elevator Vibratory Screen And Vibro Feeder Telescopic Chute Industrial Chimeny Rotary Air Lock Valve Rotary Feeder Boiler Nozzel Fuel

Get Priceconveyor any of various devices that provide mechanized movement of material as in a factory they are used principally in industrial applications but also on large farms in warehousing and freight handling and in movement of raw materials Conveyors may be only a few inches in length or they may be integrated systems several miles long Gravity roller conveyors consist of a series of

Get PriceWhen company officials decided to upgrade the dust containment on one of its primary coal conveyors they saw several potential benefits There was the safety aspect by limiting dust and spillage from one of its principal conveyors engineers wanted to reduce airborne particles and eliminate a potential source of trips and falls

Get PriceBELT CONVEYOR Belt conveyors used to transport minerals are to be found all around the world in a large number of surface and underground mining operations The idea of using the conveyor belt is not new indeed the first bell conveyors were introduced at the end of the nineteenth century the basic principles of operation have not changed

Get PriceWe can provide coal carriers loaders 1 Fixed Ship Loading Conveyor System 2 Mobile ship loader Conveyor 3 Mobile Belt Feeder for Coal 4 Others We can help you design coal carriers loading system 1 Coal Loading Port Consulting 2 Coal Loading System Design 3 Coal Loading Equipment Supplying 4 Operation Workers Training 5 Parts

Get PriceWeekly Maintenance Check the wear of the conveyor belt the checkpoint should be a certain distance away from the joint Check the operation status Whether the conveyor belt and the bracket are worn due to the deviation of the conveyor belt Whether the material has a partial load phenomenon

Get PriceBelt Conveyors Bucket Elevator Coal Handling Plant Coal Crushing System Material Handling System Gujarat India

Get PriceMaterial Impact Damage Large and bulky material can cause damage to conveyor rollers frames and belt When the material lumps and become large or excessive rollers become less effective When the lumps impact between the rollers the belt is stretched to absorb the forces and causes stress Over time the impact can disfigure the belt

Get PriceAug 25 2020Tramp metal refers to metallic scrap including bucket teeth manganese steel mantles bore crowns bar scrap chains tools and more that might break off and land in the raw material If these pieces of metal are not detected and removed the expensive crushers conveyors and other expensive downstream equipment can be damaged

Get PriceBulk Material Handling TAKRAF is recognized as a world leading technology brand when it comes to bulk material handling solutions with a specific focus on high capacity and/or solutions are designed to cater to your unique requirements and include all forms of conveying stockyard disposal facilities loading unloading equipment as well as various port facility solutions

Get PriceHeavy duty steel construction eliminates warping and bending and a powder coating adds even more excellent durability We re ready to assist you with optimal conveyor belt support and conveyor components for your transfer point solutions Contact us at 630 844 1300 today to speak with a Benetech specialist

Get PriceVery fine materials such as portland cement are loaded at terminals using belt conveyors Large lump size materials such as coal are transported from mines using belt conveyors Belt conveyors can be designed to handle capacities for any operation It is common for belt conveyors to unload ships at capacities up to 10 000 tons per hour

Get PriceBenetech believes your resources should be spent on high performing technologies and solutions that improve assets related to safety production and lower operating costs If your business is contending with conveyor belt spillage we have your specific solution Contact us at 630 844 1300 to speak with a Benetech specialist

Get PriceEvery year billion tons of coal are burned in the with 90% of that being used for electricity generation Several years ago a University of Illinois professor reported that to produce 109 kWh/year of power a plant burns 14 000 tons of coal every day He noted that the coal that goes to a typical coal fired power plant is crushed to approximately 5 cm in size before it is loaded

Get Price2 Construction and Maintenance of Belt Conveyors for Coal and Bulk Material Handling Plants Content Chapter Title Page No 1 Need for Bulk Material Handling Plants with Conveyors 3 2 Characteristics of Bulk Materials 4 3 Mechanical Components in a Belt Conveyor 11 4 Belts 15 5 Belt Standards 43

Get PriceRecommended max conveyor slope Degree Material description Url Description Shape Factor f1 Shape Factor f2 Hard Commodity Average Bulk Density Low kg/m³ Lump Size Max mm Operation 10 15 35 5 Link Coal 150 5 20 35

Get PriceASC supplies FRAS Skirting Rubber with a thicknesses of 6 19mm We supply slab rolls or 30m strip widths from 75mm up to 300mm to suit your conveyor system both above or below ground ASC custom engineers to your specifications and to cater to your application requirements Enquiry about ASC FRAS Skirting Rubber click here

Get PriceOn the smaller scale forklifts and conveyor systems also provide similar functions in terms of handling materials Conveyor systems operate as a means to transport large quantities of a material such as waste supplies or equipment over a relatively short distance these machines are very common in the coal industry to transport coal from

Get PriceSludges slurries moist cohesive materials are not recommended for this type of conveyor These materials are better conveyed in a structural ultra heavy duty conveyor like our Dynaflow drag chain conveyor Metals Mineral Mining Industry Materials Bentonite clay brown coal clay coal coke dried Coal graphite limestone etc

Get PriceCoal handling is part of the larger field of bulk material handling and is a complex and vital part of the CPP 4 OPERATION OF PADDLE FEEDER • The Paddle Feeders feed the coal on the conveyor belt from the Track hopper at a controlled rate The paddle blades projected in the hopper slot scoop the coal from hoppers and discharge it on

Get PriceFor optimal quantity measurement of the coal being conveyed to the power plant or to the individual boilers a continuous flow of material must be ensured Throughput measurement on the conveyor belts accurately determines the amount of coal transported Your benefit Reliable Reliable mass flow measurement unaffected by environmental influences

Get PriceWell planned conveyor placement operations can achieve 60% to 80% of the theoretical output rating Mulch and some fill materials have slower placement rates than stone or concrete Perfect placement solutions for Footings concrete and stone done the same day often from the same setup Tilt up panels and floor slabs Foundations Warehouse slabs

Get PriceFeb 14 2022Bulk material handling conveyors move rock construction aggregate ore or powder between two points but they re no less important than what happens at each end The conveyor needs to integrate with both operations whether that s extraction loading or deposition These processes define the material to be moved the distance and the rate

Get PriceThe dust accumulation resistant conveyor structure addresses this issue with its sloped surfaces that prevent the accumulation of coal dust on cross braces decking and door frames By

Get PriceCoal Bulk Handling with Belt Conveyors Belt conveyors are an efficient means of moving materials such as coal and proper free running of the system ensures that energy consumption is as low as possible

Get PricePipe conveyor is an important bulk material conveying equipment widely used in mining coal cement Metallurgical and other industries Playing an important role in industrial production and bulk transportation Pipe conveyor is a kind of special belt conveyor which developed on the basis of traditional belt conveyor

Get Price4 Cooling an Extremely Hot Material A very hot material discharged from a rotary kiln or similar equipment can damage your downstream process and handling equipment Common examples are limestone exiting a kiln and fly ash discharging from a boiler A screw conveyor can be designed to cool the material as it s transferred — for instance

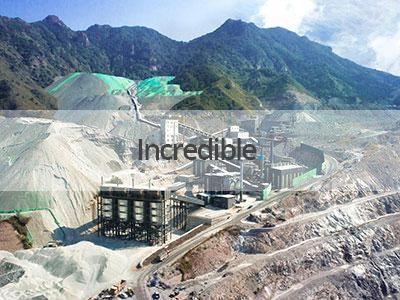

Get PriceIncredible has successfully built lots of crushing plants, grinding plants and metal ore dressing plants for our customers.

With over 30 years of experience, we become a renowned manufacturer in the stone crushing and mineral grinding industry. Headquartered in Shanghai, China, our expansive factory spans over 120 hectares, empowering us to cater to the production demands of global customers.