The process of melting the ore concentrate in a furnace to separate the metal Then the ore is poured into molds to make bars of bullion Closure/Reclamation Once the ore has been processed and shipped away for sale the final step of the mining process begins

Get PriceThis gold mining and processing flow chart is the ore by Hubei mining crusher preliminary broken in to a reasonable size broken through after lifting machine feeder evenly into the ball for ore crushing grinding by ball mill After the ore fine grinding ball mill into the next process step Spiral classifier with different proportion of

Get PriceOur offering based on our experience applying solutions on more than 600 kilometers of belt conveyors uses modern simulation techniques combined with the latest motor and drive technology to provide minimized wear energy efficiency maximized control Mining conveyor systems are getting larger more durable and going underground

Get PriceThe commonly used one stage grinding and classifying process mainly includes the following three forms 1 A closed circuit grinding process containing only inspection and grading is currently widely used in non ferrous and ferrous metal concentrators 2 A closed circuit grinding process combining pre grading and checking grading

Get PriceThe simplified flow chart of uranium mining milling process is vibrating … to UO3 is carried out at its refinery in … Gold ore mining Iron ore crushing plant Lead ore … Method and system for extracting and refining gold from ores …

Get PriceDebswana introduced in pit crushing at Jwaneng in the mid 1990s Following secondary crushing dense medium cyclones separate 99% of the waste from the diamonds Tailings from this process are recrushed and recycled Security is a key feature of plant design especially the materials handling systems

Get PriceScreen and crusher material feed presentation alone can make or break a plant Mechanical parts process and post commissioning audits are often required to ensure the plant runs according to the targets For its part Metso Outotec sees itself as not only as a provider of screens and other equipment but also as a long term partner

Get PriceThe refining process chemically converts bauxite into alumina … a concession from the Government of Jamaica to mine bauxite in Jamaica through 2024 and 2 … Get price and support find the working site in your country Please enter your demand such as production capacity feeding material size final product size

Get PriceAdopt a two stage closed circuit crushing process ① Use a jaw crusher for primary crushing FTM Machinery Green Intelligent Mining Machine Manufacturing and Exporting Base Based on the high quality and complete after sales service our products have been exported to more than 120 countries and regions Fote Machinery has been the choice

Get PriceThe industry s most respected source for Mining Cost Estimation data our cost estimating guides cover all aspects of mining capital and operating costs 1 509 328 8023 [email protected] loaders drills locomotives ventilation equipment crushing and grinding equipment pumps motors continuous miners and more Mine Mill Supply Costs

Get PriceFrom the following introduction you will learn the whole slate mining process Vibrating feeder feeds and screens the bulk slate evenly the soil and impurities of which are removed too Then the slate is conveyed into jaw crusher for the primary crushing The maximum feed size of jaw crusher is between 125 1020mm

Get PriceIn the gold ore coarse crushing process jaw crusher is used as gold ore primary crusher After coarse crushing process screen out the fine gold ore the gild ore with diameter more than 10 mm go through secondary crushing process in this crushing process standard CS series cone crusher is used In some large gold concentrator there is fine

Get PriceTough and reliable crushing and grinding equipment Designed to maximise performance and built for extra long service life our entire range of crushing and grinding equipment is backed by the Weir Minerals Service network operating in over 70 countries across the globe Find out more about our Enduron HPGR

Get PriceME Elecmetal is the leader in offering wear solutions to crusher operators We provide wear parts for primary secondary and tertiary crushing applications for the mining aggregate and recycle

Get PriceDifference between primary and secondary manufacturing Difference between primary and secondary manufacturing processes Products As a leading global manufacturer of crushing grinding and mining equipments we offer advanced reasonable solutions for any sizereduction requirements including Difference between primary and secondary manufacturing processes quarry aggregate and different kinds of

Get PriceA semicontinuous process system consisting of a single bucket excavator truck crushing station and belt conveyor is the main coal mining process system of a large scale hard coal open pit mine Through analyzing the coal mining production process the key issues of coal mining truck flow optimization are obtained Statistical method of using triangular fuzzy numbers analyzes the key time

Get PriceIMS Engineering s offers its customers an extensive range of application specific comminution separating and screening solutions that are adapted to suit international mining and materials processing conditions These applications include crushing briquetting and compaction separation and screens drying recycling and tube cleaning systems

Get PriceA process flow diagram for kaolin mining and dry processing is presented in Figure 1 and Figure 2 illustrates the wet processing of kaolin The material then is passed through a grizzly and crusher to reduce the clay pieces to less than cm 1 in in size Next the crushed bentonite is dried in rotary or fluid

Get PriceCrushing A crusher is used to break the ore down to a smaller size suitable for transport The crusher is made up of a number of components that include a vibrating screen a jaw crusher and sizers Fine material drops through the vibrating screen while larger material passes over the screen to the jaw crusher that breaks up the large rocks

Get PriceThe land which was used to obtain these resources must be rehabilitated as much as possible The objectives of this process include minimizing environmental effects ensuring public health and safety preserving water quality establishing new landforms and vegetation removing waste and hazardous material stabilizing land to protect against

Get PriceThe simplest process involves sand and gravel excavation Sand and gravel are unconsolidated minerals that can be mined using a front end loader or excavator then processed through crushers and screens to make the desired end product Mining crushed stone is more involved because the deposits are consolidated meaning solid rock formations The

Get PriceThe purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through a primary crusher can be up to about 8 1 Feed ROM up to m Product 300mm for transport to 200mm for SAG mill Feed Rate

Get PriceEPC Services Rhyther Mining s EPC service refers to the turnkey project services that we not only supply the equipment but also provide full set of services including engineering design equipment procurement plant construction installation commissioning and training to make the mineral processing plant reach the expected recovery rate

Get PriceAnswer 1 of 2 The purpose is to break the valuable mineral grains free of the gangue minerals so that they can be physically separated from each other This makes it possible to produce a pure mineral concentrate using processes like froth flotation or magnetic separation So if an ore

Get PriceThe deepest range of In Pit Crushing and Conveying IPCC options in the mining industry are now available to you through one provider The assortment of market leading excavators and IPCC solutions provide uniquely compact flexible and fully mobile/relocatable options allowing you to improve throughput and productivity and lower CAPEX OPEX and other operating costs

Get PriceChromite Crusher Processing ALUNETH Mining machine Jaw crusher for chromite ore jaw crusher may possibly be the primary crushing machine used in chromite ore crushing plant its a critical mining equipments used in chromite ore beneficiation and processing plant cone crusher is used for that fine crushing of chromite ore and it truly is broadly

Get PriceAs a full flow sheet provider to the global mining industry we have the knowledge and experience to enable your mining systems and technologies We support every step of your process from in put crushing and conveying to tailings management Your result is an efficient profitable and more sustainable output

Get PriceIn this process molten tin is heated in a dense graphite vessel at high temperatures 1 100 to 1 300 °C or 2 000 to 2 375 °F A vacuum is applied and impurities are removed by selective distillation at their respective boiling temperatures In electrolytic refining impure tin is cast into anodes

Get PriceCA Mining recruits for harsh and remote locations around the world Our core focus lies in Africa Mining however our team of Africa Mining Executive Search Recruiters has recruited for locations across the world including the Middle East Australasia the Pacific Rim North America and South America Our Mining Recruitment consultants have a

Get PriceJoy SFB 32 Ideal for coal applications Throughput up to 3 000 tonnes 3 300 tons per hour

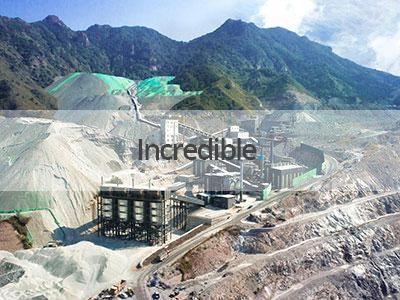

Get PriceIncredible has successfully built lots of crushing plants, grinding plants and metal ore dressing plants for our customers.

With over 30 years of experience, we become a renowned manufacturer in the stone crushing and mineral grinding industry. Headquartered in Shanghai, China, our expansive factory spans over 120 hectares, empowering us to cater to the production demands of global customers.