Jun 26 2024 0183 32 Mineral Processing Design and Operations is expected to be of use to the design engineers engaged in the design and operation of mineral processing plants and including those process engineers who are engaged in flow sheets development Provides an orthodox statistical approach that helps in the understanding of the designing of unit

Get PricePlant Design Mechanical Preparation Of Minerals plant design mechanical preparation of minerals stone Crusher Wikipedia A crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust Crushing is the process of transferring a force amplified by mechanical The earliest crushers were handheld stones where the

Get PricePlant design aims to maximize gravity flow and to provide plant access for maintenance while allowing the current gravity / CIL plant operation to continue without interruption The plant

Get Priceplant design mechanical preparation of minerals Preparation and effects of nano mineral particle Jul 21 Effect of Nano mineral Feeding on Livestock Production Use of plant materials for the synthesis of nano minerals is easier and advantageous as Lewis K Klibanov AM Surpassing nature Rational design of sterile surface materials Koch CC Synthesis of nanostructured materials by mechanical

Get PriceMar 14 2022plant design mechanical preparation of minerals Know More Coal preparation plant Wikipedia the free encyclopedia A coal preparation plant CPP is a facility that washes coal of soil and rock crushes it into graded sized chun Run of mine ROM coalCoal handlingCoal sampling Get

Get PriceThe Aggregates and Minerals Marketplace is the database dedicated to Producer members including owners presidents directors of operations quarry superintendents plant managers engineers and purchasing agents helping them find the products services they Bin Conveyor LLC Blasters Tool and Supply Company Hazen Research Inc Jacobs formerly akers Mountain States R D

Get PriceThis report contains a detailed design proc edure of a plant to manufacture Sulfuric acid from Sulfur as followed by Group 01 as per the allocations of CH 4202 Comprehensive Design Project 09

Get PriceSearch 40 Mechanical Engineer in Mineral Plant jobs now available on the world s largest job site

Get Price3 Surface mining Is a type of mining in which soil and rock overlying the mineral deposit the overburden are removed Surface mining is the predominant exploitation method worldwide Surface mining requires large capital investment primarily expensive transportation equipment but generally results in High productivity high output rate of ore

Get PriceMineral reagents Mineral reagents are the most conventional compounds The disadvantage is that a lot of these reagents must be added to the conditioning In case of a ferric chloride / lime treatment the reagents are usually and respectively 7% and 30% in masse proportioned Because of these proportions almost the same amount of mineral

Get PricePoor sample preparation practice Difficulty in obtaining copies of Best Practices for running tests Lack of experienced people to teach experimental procedures Lack of QA/QC programs within laboratories Developing and maintaining a collection of such procedures will provide many benefits to mineral processing engineers Below is discussion of the challenge and opportunity including a

Get PriceUS2664196A Process and plant for the mechanical preparation of coals and minerals by washing in a plurality of chutes Google Patents Process and plant for the mechanical preparation of coals and minerals by washing in a plurality of chutes Download PDF Info Publication number US2664196A US2664196A US290676A US29067652A US2664196A US 2664196 A US2664196 A US 2664196A US 290676 A US290676 A

Get PricePlant Design Mechanical Preparation Of Minerals plant design mechanical preparation of minerals stone Crusher Wikipedia A crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust Crushing is the process of transferring a force amplified by mechanical The earliest crushers were handheld stones where the

Get Pricegold mining flotation equipment in kenya > 200tph capacity design mechanical preparation of minerals Subaru EE20 Diesel Engine Subaru s EE20 engine was a litre horizontally opposed or boxer four cylinder turbo diesel engine For Australia the EE20 diesel engine was first offered in the Subaru BR Outback in 2024 and subsequently powered the Subaru SH Forester

Get PriceALLIED Crusher Concrete Manufacturer Allied Used Mechanical Concrete Crusher to fit Cat 330DLEL 336DLELFL DB Linkage price includes any needed repairs Used Mechanical Stump Crusher Low Price Mechanical Sand Machineries In Tamil Nadu

Get PriceSO 2 is emitted from cement plants via two main processes 1 Sulphite impurities in the limestone and other raw materials 2 Final project Report on cement industry SlideShare May 28 2024· Cherat Cement Company is an ISO 9002 certified company and follows sections on management and contract review requirements etc Expansion of the Plant The factory had the capacity to produce 1460

Get PriceBrief Introduction of Flotation Column The flotation column is mainly used for slurry flotation in preparation plant and other metallic and non metallic mine Diameter of Flotation Column 1000 4000mm Height of Flotation Column 5000 6200mm Motor Power of Circulating Pump 15 110kw Weight with water

Get PriceThe plant was designed to fit into two sea containers for transportation Resources Gold Technology Resources Gold Technology USA provide complete turnkey modular gold processing plant for design tonnages of between 500 to 2024 t/d The plant is assembled in typically nine sea containers for ease of transportation and simple light civil

Get PriceMinerals Processing Plant Design fraser lever is a leader in australia png with its minerals processing plant design expertise teamed with epcm services for seamless project integration handling mine feasibility studies mechanical engineering structural engineering this includes high level analysis of the technical aspects and preparation of

Get PriceThe high carbonation potential makes ultramafic tailings ideal aggregates for carbonated building materials This paper investigates the preparation condition of ultramafic tailings and steel slag through orthogonal experiments The results show that compressive strength has a positive exponential correlation with the CO2 uptake of the carbonated compacts The optimized conditions include a

Get PriceProcess design of the Phola coal J preparation plant o Process design of the Phola coal preparation plant by Cresswell Synopsis The 2 360 t/h two module Phola coal preparation plant represents a new era of large plant in the Witbank coalfield designed to extend its life to 2024 and beyond The plant uses the optimum processing model for

Get PricePlant Design Mechanical Preparation Of Minerals plant design mechanical preparation of minerals Coal preparation plant Wikipedia the free encyclopedia A coal preparation plant CPP is a facility that washes coal of soil and rock crushes it Know More PDF Overview of Mineral Processing Methods PDF The first process that most of the ores or minerals undergo after they leave any mine

Get PriceJun 23 2024 0183 32 Planetary ball mill is a most frequently used system for mechanical alloying since used in the mineral processing industries are mostly of the tumbling mill type used to produce finely sized products that range from 35 mesh to 10 microns 150 200TPH Cobble Crushing Plant Andesite Crushing Plant In

Get PriceThe mechanical properties of NFCs are mainly governed by plant fiber selection matrix material selection surface treatments selection and fabrication techniques selection Available literature revealed that untreated plant fibers have noncellulosic compounds and smooth surface due to which inferior mechanical interlocking and incompatibility between NFs and matrix material occurred

Get PriceThe plants take in water containing dissolved minerals from the soil through their roots This water containing minerals called xylem sap is carried by the xylem vessels to all the parts of the plant This happens as follows The roots of a plant have hair called root hairs The function of root hairs is to absorb water and minerals from

Get PriceThe minerals in coal have a major effect on the design of boilers and how they are operated With a background of 25 years in solving problems brought about by coal ash in large boiler furnaces the author reviews the chemistry and physics of ash behavior under real life conditions Chapter headings are influence of coal mineral matter on boiler design mineral impurities in coal quality of

Get PriceSeveral traditional household food processing and preparation methods can be used to enhance the bioavailability of micronutrients in plant based diets These include thermal processing mechanical processing soaking fermentation and germination/malting These strategies aim to increase the physicochemical accessibility of micronutrients

Get PriceThe initial operation is crushing and pulverization of the raw material to reduce it to a particle size that is suitable for existing concentration processes and equipment as well as for the separation of concretions and formation of particles of individual minerals

Get PriceRetting is the process for the preparation of bast fibres This is done by 3 methods Microbial steam and mechanical process Microbial method is widely followed Using this method the lignin bond between parenchyma and sclerenchyma is broken Breaking the bond facilitates easy procurement of skin from its core It is then washed and dried to convert hard skin to soft fine thread The jute fibres

Get PriceIn this study monoammonium glycyrrhizinate MAG was introduced into cetyltrimethyl ammonium bromide CTAB modified ZnO/attapulgite APT via a mechanical process to form performance enhanced antibacterial nanocomposites MAG/C ZnO/APT The APT supported ZnO nanocomposite ZnO/APT was prepared by a conventional precipitation method and 20 50 nm of globular ZnO nanoparticles

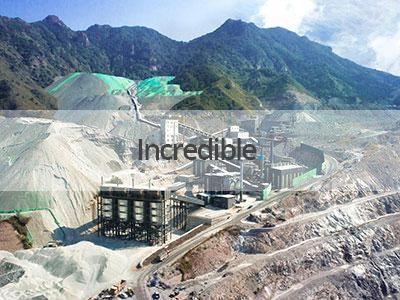

Get PriceIncredible has successfully built lots of crushing plants, grinding plants and metal ore dressing plants for our customers.

With over 30 years of experience, we become a renowned manufacturer in the stone crushing and mineral grinding industry. Headquartered in Shanghai, China, our expansive factory spans over 120 hectares, empowering us to cater to the production demands of global customers.