CMC series track mounted mobile jaw crushing plant is the favored primary crushing equipment for various hard and highly corrosive rocks and minerals Utilized to crush materials in the primary stage it mostly adopts the configuration form of a feeder a jaw crusher Jaw Crusher JC96 JC106 JC116 Feed Opening Size mm 930 580

Get PriceDOVE Jaw Crushers are ideal rock crusher machines highly efficient and economical for handling Primary and Secondary stone crushing applications of various ores and bulk materials with compressive strength below 320 Crushers are supplied in Stationary complex plant configuration or in Portable and Mobile Designed with optimum cavities and height in relation to feed

Get PricePrimary crushing plants are the first step in material processing and/or link between mining truck and belt conveyor train or road TAKRAF s range of primary crushing plants Primary crushing plants can be equipped with gyratory crushers jaw crushers twin shaft sizers double roll crushers impact crushers or hammer crushers depending on material properties and required throughputs

Get PriceA Crushing plant is one stop crushing installation which can be used for rock crushing garbage crushing building materials crushing and other similar operations Crushing plants may be either fixed or mobile Raw materials are evenly and gradually conveyed into jaw stone crushing equipment for primary crushing via the hopper of vibrating

Get PricePrimary crusher Primary crushing plant All industrial jaw crusher PE750 1060 stationary compact primary jaw crusher PE750 1060 Capacity 110 t/h 250 t/h Weight 27 t Motor power 110 kW 150 kW PE750 1060 jaw crusher is used in the first process of coarse and medium crushing various minerals and rocks

Get PriceHow does the Concrete mixing plant works Concrete mixing plant is divided into four parts gravel feed powder cement fly ash bulking agents etc to feed water and feed additives transmission and storage stirred their workflow shown in Figure 1 the mixer control system power into the human machine dialogue operation interface system initialization process including recipe

Get PriceMobile Crushing plant 30 800tph stone crusher plant sand making plant HOME PRODUCTS SOLUTION FAQ Who We Are CONTACT US Russia 0086 19139990572 Home Product Mobile Crusher Machine Jaw Crusher Quick details Application Primary crushing Feeding size 210 1020mm Capacity 5 800tph

Get PriceJaw crusher is a kind of stone crusher machine which is widely used as primary or secondary crusher in stone crushing plant The purpose is to reduce hard stone material to a small size that it can be transported by conveyors to the next crushing stages 100 1200mm Feed Size 280KW Motor Power 5 700t/h Processing capacity

Get PriceApplication Primary jaw crusher is mainly used for crushing medium size stone and large

Get PriceCONSTMACH mobile crushing and screening plants for crushing of any type of stones with capacity changing from 60 to 300 tph Premium quality 2 years warranty 90 542 7661315 info Home Presence of primary jaw crusher enables to crush big and hard rocks On the other hand thanks to the secondary impact crusher it is

Get PriceThe Cedarapids CRJ3042 plant combines the popular JW42 jaw crusher with a high stroke 42 x 20 1067 x 6096 mm vibrating grizzly feeder resulting in a high production portable crushing machine This plant includes a hopper design that can handle severe primary crushing applications The highly mobile CRJ3042 is easy to operate and

Get PriceJaw Crusher The Finlay J 1170AS mobile jaw crushing plant provides the flexibility of a crushing and screening plant on one machine This aggressive machine features a detachable on board sizing screen The heartbeat of the machine is a robust hydrostatically driven Terex jaw chamber which provides high capacity with large reduction ratios

Get PriceFeatures The jaw crusher modular crushing plant is mainly used for mineral and rock primary crushing processing The different specifications of the feeders jaw crushers belt conveyors and module structures are designed according to different production capacity The matched feed bin is designed according to different feeding types which is

Get PricePrimary Crushing This is the first stage of the crushing process In general the size of the feed material which is between 800 and 1500 mm is reduced to between 150 and 300 mm WHAT IS A JAW CRUSHER / JAW CRUSHER This is a type of crusher that is widely used in the primary and secondary crushing processes Plants Mobile Concrete

Get PriceJaw crushers are an extremely common crushing plant in quarries mining plants and construction waste disposal centres using compression to crush hard ore concrete brickwork info 8615838176062 English

Get PriceThe Jaw Crusher includes vibrating feeder jaw crusher impact crusher vibrating screen belt conveyor and centrally electric controlling system etc The designed capacity is from 50t/h to 500t/h To meet customer s specific requirement we can also add other equipments such as cone crusher dust catcher on the production line

Get Price2024 Omega wheeled mobile jaw crusher for sale The Omega J960 wheel mounted jaw crusher features a robust design for use in Quarry Mining and C D Waste Applications Primary Plant Ltd Kilkerrin Ballinasloe Galway Ireland Contact Us Tel 00353 87 806 3652 E info Site Map About Us Products After Sales

Get PriceFABO MJK Series are a mobile type Jaw crushing plant that is suitable for especially hard and abrasive stones and other type of stones with hardness level is hard such as a basalt Condition New MLS Number 2024 FABO CLK 110 SERIES 180 320 TPH PRIMARY JAW CRUSHER

Get PriceOct 27 2020The jaw crusher is the first stage in the crushing and screening process the main purpose of this stage is to crush the rock into a conveyable size In addition to this other tasks are also performed such as Removal of natural fines soil or other contaminants Production of coarse products such as road base sub base ground base or similar With this in mind the design of the primary jaw crusher stage is more than just getting the blasted material into the jaw crusher

Get PriceTCI designed and built this primary dump hopper conveyor system dual screen structure and 150 radial stacker to help our customer meet the demands of the

Get PricePortable jaw crusher plant is a versatile tool for crushing contractors who need to process both hard rock and any rock based recycle materials equally effectively The unit can achieve crushing capacities of up to 350 mtph and is well suitable as a primary crusher in multi stage process As an option it can be equipped with active setting

Get PriceMobile Jaw Crusher Used in Iron Ore Processing Iron ore crushing plant plays an important role in iron ore mining processing and beneficiation CathayPhillips Mobile Jaw Crusher Plant usually take as the iron ore crushing plant It is equiped with different crushing equipment from primary crusher secondary crusher tertiary crusher washing

Get PriceOur products could fully meet the needs of primary crushing secondary crushing tertiary crushing and even four stage crushing and feeding conveying and screening The Camelway Mobile Crushing and Screening Solutions are widely used in aggregate production open pit mining construction waste disposal etc Over the years Camelway has always

Get PriceJaw crusher invented by Whitney Blake in 1858 is a primary stone crushing machine for reducing minerals or stones into smaller sizes It is a must have machine in wide range of fields like mining quarrying and construction industries The most important parts are jaw plates made of high manganese steel which makes jaw crushers suit for the

Get PriceCONSTMACH Primary Jaw crushers are designed to handle initial crushing process of any type of material from the softest limestone to the hardest granite with 50 to 600 tph capacity CONSTMACH Jaw Crushers are used as the first stage crushers in our stationary and mobile type crushing plants High flywheel speeds jaw angles safety plates

Get PriceEssa JC3000 Jaw Crusher The heavy duty general purpose Essa JC3000 Jaw Crusher is a well proven highly productive primary crusher used in sample preparation and plant applications More powerful than the JC2000 it is suitable for higher workloads and can handle large core and lump crushing

Get PriceRaw material of various sizes are brought to the primary crusher by rear dump haul units or carried by a wheel front end loader Primary crushing reduces excavated rock to a more manageable size There are different types of primary secondary and tertiary crushers including jaw crushers gyratory crushers impact crushers and autogenous crushers

Get PriceThe term primary crusher by definition might embrace any type and size of crushing machine The term implies that at least two stages of crushing are involved but in many cases the machine which performs the function of initial crusher is the only crusher in the plant The factors influencing the selection of a crusher for this service are much the same regardless of how many crushing stages there are in the flowsheet therefore the term primary crusher by common usage is

Get Pricestationary primary Capacity 5 t/h 1 100 t/h Motor power 15 kW 280 kW Opening height 150 mm 1 500 mm Stone crusher is to break blocks of stone mining ores concrete and other building materials into a smaller specific grain size It has types of jaw crusher cone crusher impact crusher

Get PriceLippmann LJ3062W Portable Electric Primary Jaw Recycling Crushing Plant Call for specs and pricing Get Shipping Quotes Apply for Financing Featured Listing View Details 1 LJ3048 30 x48 heavy duty jaw crusher plant Call specs and pricing Get Shipping Quotes Apply for Financing Featured Listing View Details 4 Unsave Save

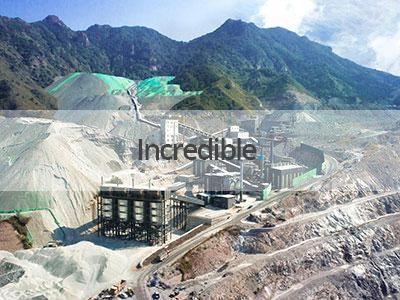

Get PriceIncredible has successfully built lots of crushing plants, grinding plants and metal ore dressing plants for our customers.

With over 30 years of experience, we become a renowned manufacturer in the stone crushing and mineral grinding industry. Headquartered in Shanghai, China, our expansive factory spans over 120 hectares, empowering us to cater to the production demands of global customers.