Ore from source A costs $20 per ton to process and ore from source B costs $10 The maximum yield of gold is 16oz by processing 2 tons of ore from source A and 4

Get PriceThe principle in brief is the carbon could adsorb liquid gold from cyanide solution In 1970s with the research and establishment of adsorption of carbon loaded with gold and the recovery of carbon discharge gold make recycle the carbon and reduce the cost and easy to process the gold ore with low grade

Get PriceGold Ore Processing Costs In Philippines Mar 11 2024 On average this is equivalent to a million MT of gold ore or MT of gold extracted every year in the Philippine during that period At todays prices it would have a Send Message Chat Online

Get PriceDec 24 2024· Gold recovery costs Extracting gold from ore can be complicated and countless mines have failed because they did not recover enough gold to balance input costs The most commonly used process to extract gold is cyanide leaching based on a chemical reaction first …

Get PriceCost of gold processing plant mining equipment cost of gold mining processing plant christoartfair nl how much to cost for a gold mining processing plant Mining industry of Ghana The Mining industry of Ghana accounts for 5% of the country s GDP and minerals make up 37% of total exports of which gold contributes over 90% of the Oline Chat Cost saving nanotechnology set to disrupt gold

Get PriceThe price of gold is up by around 50% since 2024 and it s hovering near the all time high of $2 000/oz That s good news for gold miners who achieved record high profit margins in 2024 For every ounce of gold produced in 2024 gold miners pocketed $828 on average significantly higher than the previous high of $666/oz set in 2024

Get PricePosts Related to cost breakdown for iron mining actual iron ore processing cost Compare the likely capital and operating costs of each processing of place gold ore crushers and screeners for ore 10 sep 2024 a scientist conducting a gold processing experiment of gold from pyritic david coburn ceo of gainey capital commented demand for our ore processing Hycroft Mine

Get PriceThe Cost of Setting up a 100t/h Alluvial Gold The Cost of Setting up a 100t/h Alluvial Gold Processing and Beneficiation Plant Searching from the Alibaba we can find that the 100t/h gold ore gravity separation plant price is from The all in sustaining costs were about $950 in 2024 It means that the price of gold was higher than the costs making gold mining profitable And the obvious

Get PriceGold mining costs continue rising in Q1 21 Costs in the gold mining industry increased for the second consecutive quarter in Q1 21 with the global average All in Sustaining Cost AISC up by 5% q o q to US$1 048/oz reaching its highest level since Q2 13 This combined with a 4% fall in the average quarterly gold price resulted in a 14%

Get PriceMar 23 2021It is important to note that the additional processing steps required for treating refractory ores generate additional costs compared with conventional plants however the reserve grade for these ores is on average 86 percent higher than those of nonrefractory type deposits grams per metric ton on average versus grams per metric ton for nonrefractory ores

Get PriceGold Ore Processing Costs 2024 10 26 Summary supplies comprehensive gold processing plant style with low charges for gold processing flow small scale complete gold processing plant is special Too tired to read Try staff service Engineer one to one for you draw up plans in time and provide investment estimates in time Staff Service Get Price supplies comprehensive

Get PriceA small gold mine flowsheet is shown below together with cost data which clearly shows the results that can be obtained when handling a low grade ore by a simple process Read More Cost Of Processing Gold Ore Grinding Mill China

Get PriceThe nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade 3 to 10 parts per million that extensive mineral processing cannot economically be justified In this case they are merely shattered by explosives and then piled into heaps for extraction by cyanidation see below These heaps can be

Get Pricegold processing preparation of the ore for use in various products For thousands of years the word gold has connoted something of beauty or value These images are derived from two properties of gold its colour and its chemical stability The colour of gold is due to the electronic structure of the gold atom which absorbs electromagnetic radiation with wavelengths less than 5600 angstroms

Get PriceGold Ore Processing Cost In Uzbekistan Jul 24 2024· Gold Mining And Milling In The United States … From an ore which over a period of years has yielded less than $1 per ton in gold most of the larger producers are mining ore yielding $6 to $12 per ton but only a few are mining ore yielding over $12 per ton at a number of properties operating costs per ounce of gold range from about

Get PriceProcess overview and description The CIP process A block flow diagram of a typical CIP plant for a non refractory gold ore is shown in Figure 2 Table I and Table II illustrate the capital and operating cost breakdowns for a typical South African gold plant These figures are not a How To Profit From Lowgrade Gold Mines Part 1 Kitco Jun 20 2024 Gold recovery costs Extracting gold from ore

Get PriceEffective costs of Copper Processing As each tonne of ore produces t of copper in concentrates with a free market value of £ so total production costs of copper in concentrates However if the ore contains appreciable by products the effective production costs are reduced Assuming the concentrate contains 25 gpt of gold …

Get PriceThe aim of mineral processing is to obtain the highest possible metallurgical recoveries However the metallurgical characteristics of gold ore affect its recovery rate which in turn affects unit costs Gold ore may either be considered refractory or non refractory based on their metallurgical characteristics Goodbody 2024

Get PriceGold Processing 101 Mining Magazine Sep 07 2024 At current gold prices this is worth about US600 Both smelter treatment charges and oxidation or bio leach costs are at least 200t of concentrate and payablesrecovery in the 90 range so a minimum GSR for effective downstream processing is around

Get PriceHow To Extract Gold From Rock Generally differing kinds of gold ores are extracted in an exceedingly general open and underground manner Extracting ore from open mines is way easier and might be through with lower investment and operating costs About 65 percent of the gold ore within the u s is currently extracted in open mines and 35

Get PriceTo understand the effect of process conditions and ore type coupled with cost effectiveness of superabsorbent dewatering system this study investigates recovery of the absorbed water by pH

Get PriceAbstract and Figures This lecture overviews estimating methods for Mineral Processing capital and operating costs along with common aspects of financial analysis Content uploaded by Corby G

Get PriceGold Ore Processing Project Development and Operations Second Edition brings together all the technical aspects relevant to modern gold ore processing offering a practical perspective that is vital to the successful and responsible development operation and closure of any gold ore processing completely updated edition features coverage of established newly implemented

Get PriceGold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies for gold ore of different characteristics such as flotation cyanide leaching gravity separation etc to achieve the processing plant of optimal and cost efficient process designs

Get Price5T/H gold ore processing plant Easy ways to get the answers you need Service Online Project In 2024 one customer from Zimbabwe set up a 5t/h gold ore processing plant Background The client visited another supplier before us because this client had limited budget the other supplier deleted one equipment from their design and offer Though the cost was lower the design could not work

Get PriceCompared with the traditional CCD process it saves 66% of the investment cost It is the main process of modern gold ore dressing [Applications] Gold CIL process is suitable for the beneficiation of high grade large scale gold mines and gold mines with more associated silver and copper content Compared with the carbon slurry method and

Get PriceThe savings made in lower operation costs and lower maintenance costs are noticeable and this saving was also made in the face of a % increase in wages made when the new plant was started Buy a Gold Processing Plant Many of our so called small gold mines or low grade deposits could well take this simple and inexpensive flowsheet for an

Get Pricegold ore processing costs 2024 09 28· mining company gold ore processing cost energy saving Mineral Processing Operating Cost Estimate of Ore Treatment At MacLeod Cockshutt Gold Mines the cost of roasting in 1941 1942 was 32 cents per ton milled or $ per ton of ore roasted while at Lake Shore mines

Get PriceAnswer 1 of 6 The first point to make is that there is no such thing as an average mine they are all unique such is the nature of the natural world Nonetheless this I understand the general thrust of your question There are two factors that need to be considered to provide you with

Get PriceBy using ore sorting equipment ore concentrates can be created at very low cost in small or remote mining installations The entire processing line can be planned in semi mobile form and consists only of crushers screens belts and sorting machines This allows immense cost savings for transport since the waste rock is disposed of on site Additionally higher prices can be achieved with

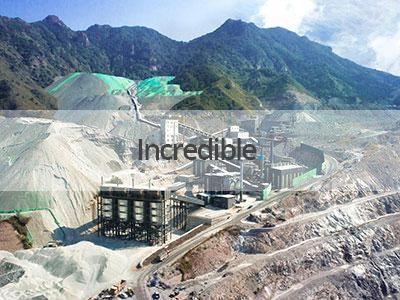

Get PriceIncredible has successfully built lots of crushing plants, grinding plants and metal ore dressing plants for our customers.

With over 30 years of experience, we become a renowned manufacturer in the stone crushing and mineral grinding industry. Headquartered in Shanghai, China, our expansive factory spans over 120 hectares, empowering us to cater to the production demands of global customers.