Min Order 1 Set FOB Price US $1 99999 / Unit Zinc Ore Crusher … 3000 MT per lilimingne of crushing grinding thickening plant of Uranium ore …

Get Priceintensities measured and the concentration of an element This means that quantification by means of external calibration with a linear regression line is possible The calibration should be adjusted to the working range in question Even for the lowest concentration values sufficient measuring sensitivity and reproducibility must be assured

Get PriceAbout products and suppliers If you are in the mining industry or have a business involving minerals manganese ore concentration plant is an essential piece of equipment for you At you can find a great selection of manganese ore concentration plant machines that work precisely and can ease your work ore concentration plant machines deliver high volume

Get PriceFor these reasons it is recommended that drinking water have no more than mg/L or parts per million of iron and less than mg/L of manganese The Environmental Protection Agency has also set a Health Advisory for manganese of mg/L A Health Advisory is a non enforceable drinking water standard which is meant to alert

Get PriceThe plant processing the ore presently produces tailing products having iron mineral content of between 20 and 22% Ajaka 2024 which is considered a significant loss of value

Get PriceNov 30 2024 Keeping it mobile and modular The Iron Knob crushing and screening plant was designed to have a 10 year life expectancy making the use of mobile crushing and screening equipment as a more cost effective solution compared to a fixed infrastructure solution The plant was originally estimated to cost approximately $40 million but by using

Get PriceAug 11 2024 0183 32 mineral water plant feasibility study pdf Mineral Water Plant Feasibility Study Pdf Feasibility Study Of Mineral Processing Mobile Pre feasibility study water bottling plantPre feasibility study purified bottled water pref 3september 2024 rev 1 8 for the purpose of this feasibility study two samples of kwsb water has been taken and their stone

Get PriceFor selection of appropriate techniques it is necessary to carry out first the mineralogical assessment of the ore so as to get the insight into the ore and to know the gangue association and grain size etc There are several issues relating to categorization and beneficiation of low grade iron ores

Get PriceCoal beneficiation plant Construction Recycle Plant Copper ore beneficiation plant Dolomite stone processing plant Feldspar processing plant Feldspar stone processing plant Gold ore concentration plant Granite stone processing plant phosphate flow rock kudremukh magnetite iron ore beneficiation process flow sheet flow chart of silicon

Get PriceIron Ore Process With Pelletization Iron Ore Beneficiation And Pelletization Plant iron ore beneficiation and pelletization plant The pelletization process is the primary consumer of binders in the iron ore industry the selection of an appropriate binder type and dosage is of critical importance in producing good quality pellets at a reasonable price binders accomplish two very

Get PriceWet Grinding vs Dry Grinding Plant in Ore Concentration Myanmar wet grinding vs dry grinding grinding vs dry grinding in ore concentrate wet grinding vs dry grinding plant in ore concentration myanmar compare XSMhas been serving the aggregate crushing industry for over 20 years it is one Read More Chat On Line

Get PriceUsually iron ore processing 26 plants include iron ore crusher grinding mill beneficiation plants and other assistant equipments High productivity and low maintenance are some of the traits that all of XSM s processing solutions have in common and that make the daily iron ore process a routine yo

Get PriceSep 8 2020According to their chemical composition iron ore can be divided into magnetite hematite limonite and siderite The specific magnetic susceptibility of the material is different and iron ore is divided into strong magnetic and weak magnetic minerals which also provides a basis for the selection The beneficiation process of iron ore of different nature is also completely different

Get PriceAug 4 2022There are many factors affecting the work of the shaking table among which the main stroke the number of strokes the concentration of ore feeding the amount of ore feeding the flushing water for the ore body the lateral slope of the bed surface and the nature of the ore 1 Stroke and stroke times The stroke and the number of strokes mainly affect the loosening stratification

Get Priceiron ore concentration plant supplier iron ore concentration plant supplier 415 Iranian Central Iron Ore Company SAMI intends to supply and development of one 5 000 000 tons per year Pelletizing plants with associated infrastructure of one 2 500 000 tpy Pellet Plant iron ore DR grade pellet by using iron ore concentrate as feed material from one 4 000 000 tons per year

Get PriceCDEIrelandtv 11 01 iron ore fines after being washed and dewatered through the CDE Asia iron ore washing plant … cake moisture content … Dewatering of … iron ore filter cake manufacturing process BINQ Mining

Get PriceThis chrome ore concentration plant with a capacity about 10 TPH the feeding grade is between 15 20% while the final concentrate grade is around 45% Lab Equipment Selection Minin Get Price Iron ore beneficiation plant for concentration process Iron ore beneficiation plant is used for concentration process Get Price

Get PriceThe plant is operated at conditions as generally known in the art for example the reduction of iron ore may be accomplished at temperatures in the order of from 1600° F to 2100° F In the direct reduction plant iron ore is converted to iron and in addition the calcium oxide present in the flux is converted to calcium sulfide

Get Price2024 2024 location stary oskol russia renaissance heavy industries constructed the pelletizing plant with annual capacity entitled stoilensky mining and beneficiation plant the biggest and most efficient iron ore production plant in the world current equipment allows production capacity to reach up to tons

Get PriceThe Kudremukh plant in Karnataka was the first big iron ore beneficiation plant in India It mainly processes complex haematite and magnetite ore It got pelletisation facility for pellet making from the concentrate of beneficiation plant Pellets are not for domestic consumption rather exported for revenue generation

Get PriceExpansion of Iron Ore Beneficiation Plant Ex Summary In the output Washed Fines will be about 70% and Discards will be about 30% Discards will have 17 20% iron content and shall be given to bricks manufactures within 50km radius it can also be used to fill the abandoned mine pits in nearby area Plant Process details

Get PriceAnalytical electrolysis equipment is a set of gold ore beneficiation equipment that obtains gold mud from goldladen carbon through desorption and electrolysis under normal temperature and pressure conditions this equipment can well desorb the goldladen carbon produced by the gold mine coal pulp plant and heap leach plant 2

Get PriceMar 02 2024 Flotation Cell Plant For Gold Processing Magnetic Separator Flotation Cell Plant For Gold Processing Magnetic Separator China Frame Construction Series Iron Ore Magnetic Separators Flotation cell for gold copper iron ore cone magnetic separator motor size wet low intensity magnetic separators he heart of the magnetic separator is the magnetic drum assembly which is composed of

Get PriceIron ore crusher plant Features 1 Jaw crusher owns simple structure easy maintenance2 Jaw crusher owns stable performance3 Jaw crusher owns even final particles and high crushing ratio iron ore crusher plant includes vibrating feeder jaw crusher impact crusher vibrating screen belt conveyor etc KeyWord Tag

Get PriceSep 25 2024· concentration density gangue material gravity separation iron ore beneficiation Jig Jigging Low grade iron ore Low grade Iron Ore Beneficiation and the Process of Jigging Iron ore resources are getting consumed at an accelerated rate because of the growth in the production of iron and steel

Get PriceThe Lower grade sources of iron ore generally require beneficiation using techniques like crushing milling gravity or heavy media separation screening and silica froth flotation to improve the concentration of the ore and remove impurities The results high quality fine ore powders are known as

Get PriceTanzania Iron Ore Washing And Processing Plant Images 1000tpd Magnetite Iron Ore Beneficiation Line Processing Plant picture from Zhengzhou Hengxing Heavy Equipment Co Ltd view photo of Magnetite Iron Ore Processing Plant Iron Ore Concentration Plant Copper Ore Processing PlantContact China Suppliers for More Products and Price Details

Get Pricedisk filter iron ore agglomeration processing Agglomeration Technologies for the Middle East December 10 2024 Dubai 18th Middle East Iron Steel Conference Costumer Plant Location Country Order Feedstock Capacity [mtpy] Indurating Machine Mixing Area [m²] Width [m] Gol e Gohar Iron Ore Co Gol e Gohar Sirjan Iran 2024 Mixed Ore 5 0 624 4 Drum Samarco 4 Ponta de Ubú Espírito Santo

Get PriceDesign Of A Crushing System That Improves The has to follow these three steps crusher selection crusher layout and process design 24 Crushers A crusher is a tool or machine that is used to reduce the size of a large solid particle to a smaller solid particle The ore can have a size of up to 400mm There are many types of crushers but the major ones are the jaw gyratory and the cone

Get PriceDepending on the plant configuration and availability of recycled steel other sources of metallic iron such as direct reduction iron DRI or hot metal can also be used in the EAF route In 2024 the BF BOF and EAF routes respectively accounted for % and % of the world s total steel production another % of the world s steel

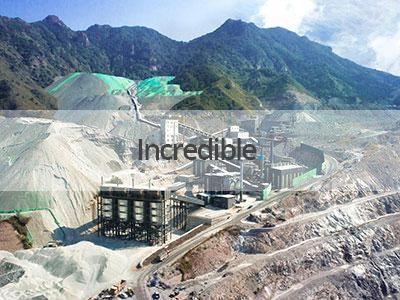

Get PriceIncredible has successfully built lots of crushing plants, grinding plants and metal ore dressing plants for our customers.

With over 30 years of experience, we become a renowned manufacturer in the stone crushing and mineral grinding industry. Headquartered in Shanghai, China, our expansive factory spans over 120 hectares, empowering us to cater to the production demands of global customers.