Coal Mining According to the Kentucky Department of Mines and Minerals million tons of coal was mined in Kentucky in 2024 62 percent 81 million tons was from underground mines and 38 percent 50 million tons was from surface mines There were 264 active underground mines and 240 active surface mines in Kentucky in 2024

Get PriceA surface mining B underground mining C acid mine drainage D secondary recovery a Acid mine drainage occurs when In some areas of the world streams have a steep gradient and constant flow of water so hydroelectricity may be generated without a reservoir t

Get Pricequality impact Mining typically increases the amount of oxygen in disturbed soils and rock as well as increasing water mobility By increasing the surface area of rocks as well as the pore volume around rocks mining activity allows acid producing reactions to occur more quickly At may older underground mines located in steep terrains such

Get Pricesurface mining and reclamation activities Affected area means when used in the context of underground mining activities all surface land and water resources affected during the term of the permit 1 by surface unless the operation is located in steep slope areas and a steep slope AOC variance in accordance with subsection of this

Get PriceA mining company will need tools for exploration extraction and remediation or reclamation at mining sites Miners use hydraulic shovels called power shovels to dig out coal clear debris and remove rocks in surface and underground mining Miners use a range of vehicles such as bulldozers mining trucks and loaders

Get Price5 Reporting and Investigating Blocked Passage Through the Tailgate Side of Longwall Mining Operations in Coal Mines See Part 50 in Volume III of this Manual 103 a Mandated Inspections Section 103 a of the Act requires a minimum of four inspections a year for underground mines and a minimum of two inspections a year for surface mines

Get PriceSurface mining accounts for about 85% of the overall mineral exploitation in the US The major countries using surface mining include the US Canada Mexico Peru India China Chile Brazil Indonesia Ukraine Angola and Australia Some of the prominent players of the global surface mining market include Goldcorp Teck Rio Tinto BHP

Get PriceSurface coal mining methods in the steep terrain of the central Appalachian coalfields include mountaintop removal contour area and highwall mining Coal mining operations are found in Kentucky West Virginia Virginia Maryland Pennsylvania Ohio Alabama and Tennessee Basic Information What is surface coal mining in Appalachia

Get PriceSurface Mining 1 Strip Mining Strip Mining is used when coal is near the surface of when the overburden is unstable As mining progresses the overburden is placed in the previous mine cavity The mining is done in long narrow strips The waste dirt and rock that they take off of the top of the next strip is to put on top of the last one

Get PriceDeposits with steep dips Gold copper silver and zinc mines Underground structures requiring vertical excavation Ores that can be stored for long periods Long wall Mining Long wall mining is a method in which a long horizontal wall of ore is excavated from one of its faces This wall is usually several miles long and hundreds of meters wide

Get PriceUnderground Mining It is one of humanity s oldest and most impressive engineering activities extracting an ore or mineral from many hundreds of feet deep underground From the days of laborers toiling deep inside narrow rickety and ill supported tunnels using crude pickaxes and with only candlelight to guide them in their quest for gold

Get PriceAFRICAN MINING BRIEF JANUARY 2024 ThoroughTec has been designing and manufacturing simulators for over 20 years and is the leading simulator system supplier to the South African Military It is also the largest global supplier of both surface and underground simulators in the mining and construction industries with

Get PriceJan 3 20222 As used in this MOU surface coal mining operation is defined in the Surface Mining Control and Reclamation Act of 1977 SMCRA Section 701 28 The phrase surface coal mining operations resulting in the placement of excess spoil fills in the waters of the United States is intended to apply generally to any mountaintop mines which

Get PriceHighwall mining is an adaptation of auger mining Instead of an auger hole an entry into the coal seam is made by a continuous miner remotely operated from a cabin at the surface The cut coal is transported by conveyors behind the miner to the outside Using a television camera the operator can see and control the miner s progress

Get PriceProduced by tunnelbuilder ltd for Atlas Copco Rock Drills AB SE 701 91 rebro Sweden tel 46 19 670 7000 fax 7393 Publisher Ulf Linder Editor Mike Smith mike Senior Adviser Hans Fernberg Picture Editor Patrik Johansson

Get PriceHAC System Ideal for both mining and industrial applications including handling of wet or sticky materials Ideal option for steep angle applications Pressing mechanism secures material toward center of belt sealing the belt edges together Uses standard idlers and rolls for greater availability of these replacement components

Get PriceStrip mining falls under the category of surface mining an umbrella term that describes specialized mining techniques such as open pit mining dredging and more These mining operations remove top layers of soil and rock approaching mineral deposits through the surface rather than from underground Miners have utilized strip mining for

Get PriceTopic 5 Mining Methods Part I Surface mining 1 Topic 5 Mining Methods Part I Surface mining Hassan Z Harraz hharraz2006 2024 2024 Prof Dr Harraz Presentation This material is intended for use in lectures presentations and as handouts to students and is provided in Power point format so as to allow customization for the individual needs of course instructors

Get PriceAug 12 2022Room and pillar mining is a type of underground mining where the miners clear out swaths of underground ore As a result they leave behind underground spaces rooms separated by sections of intact or pillars that support the overhead rock Therefore the rock does not collapse on the rooms Room and pillar mines allow for continuous mining

Get PriceOpen Pit Mining Predominant exploitation method worldwide Open pit/ open cast mining is usually used to mine a near surface deposit and deposits of low economic value and strip ratio is important for the operational economy Methods are characterised by high productivity low operating cost and good safety conditions Deposits are generally mined in benches or steps

Get PriceSurface Coal Mining Methods in Australia 7 Fig 4 Dragline Working Section Gianazza 2024 Fig 5 Box cut strip cuts and spoil piles Humphrey 1984 mining access are either taken through the over burden dump as a valley dozed through the spoil pile parallel to the strip created in the highwall either parallel or at right angles to the

Get PriceThe transportation sector in the model attempts to determine the actual routes that would be followed in coal shipping The main importance of surface mining reclamation requirements for underground production may be for new investment on steep slopes in Appalachia since reclamation costs are the highest for steep slope surface mines

Get PriceWhile production has been rising from about 1960 the production from areas west of the Mississippi exhibited steep growth from the 1970s Coal production reached a high of 1 172 million tons in 2024 Where surface mining is not feasible underground mining of the coal seam is generally conducted The coal is accessed by suitable

Get PriceScaffold platforms and crane lifts are now being replaced by specialist equipment that is capable of tracking up and down slopes providing a safe working platform to undertake the necessary sampling and drilling works Many of the UK s earth fill dams were built in the late 19th or early 20th century and while well constructed with the tools

Get PriceScenario 2 Underground mining below existing open pit Scenario 3 Open pit mining through existing underground working Once the cave has broken through to surface the crater itself represents a very deep and steep open pit scenario The sheer scale of the modern cave and the final excavation warrants a more regional

Get PriceUnderground Mining As the name suggests underground mining refers to mining that takes place below the surface layer of the earth This includes underground mining techniques such as the bord and pillar method and the longwall method These operations usually entail the construction of a tunnel as well as supporting essential infrastructure

Get Price59268158 Underground Mining Free ebook download as Powerpoint Presentation ppt PDF File pdf Text File txt or view presentation slides online 033 Mining in Steep Orebodies Surface Mining Abet Nego Mining Methods RajuRamRain Stowing Nitesh Shah Shaft Technology King County

Get PriceUnderground mining is used when surface methods are unsuitable The deposit may be too deep or a strange shape or sometimes the land over the resource is too steep or has a significant value A series of tunnels is created through the coal seam being mined The overlying rocks are supported by pillars of coal that remain between the tunnels

Get PriceUnderground mining can be considered to be more acceptable than surface mining from environmental and social perspectives since it often has a smaller footprint than an open pit of comparable capacity The main advantage of underground mining compared to surface mining is that in general only the ore is extracted and waste rock is left behind

Get Priceof underground coal mining operations and surface coal mining in special areas or in special circumstances such as steep slope mining Persons who propose to conduct surface coal mining and reclamation operations which include surface effects of underground mining by definition must apply for and receive permits

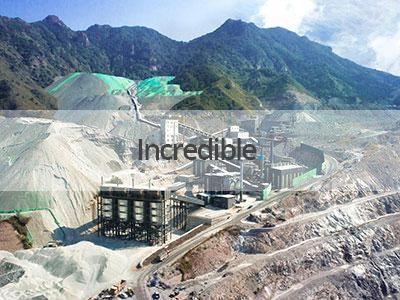

Get PriceIncredible has successfully built lots of crushing plants, grinding plants and metal ore dressing plants for our customers.

With over 30 years of experience, we become a renowned manufacturer in the stone crushing and mineral grinding industry. Headquartered in Shanghai, China, our expansive factory spans over 120 hectares, empowering us to cater to the production demands of global customers.