vibrating screener ELK U series for bulk materials 2 motor inclined Engine power 30 kW Weight 19 000 17 500 15 000 kg Screening surface 12 10 m² General machinery top driven screens vibrate elliptical The direction of the ellipse is right ahead on behind in front of the screen right ahead Material flow rate is more than at

Get PriceLearn more about how we are celebrating here Since 1921 Simplicity has provided vibrating equipment into virtually every industry requiring the separation of materials into various sizes With a strong legacy of providing the highest quality equipment we are proud to be the preferred brand for applications ranging from rock quarries to

Get PriceMetso Outotec LH Series horizontal screens are designed for tough duty high capacity applications such as mill discharge coal preparation and fine wet screening washing and dewatering Metso Outotec LH Series horizontal screens are most commonly used in minerals processing of all metallic and non metallic ores such as copper gold

Get PriceIn mining operations vibrating screen is one of the screening equipment that is often used Nowadays most of the vibrating screens on the market are linear vibrating screens and circular vibrating screens These two types of vibrating screens can also be divided into various types according to the screening materials usage scenarios and output

Get PriceThe usual target is a screening efficiency of 95% An efficiency of 99% will equate to a significant loss of capacity Screening efficiency is the ratio of undersize material in the feed that actually passes from the screening media to the undersize material that should pass from the screening media This ratio is desired to be 100% however

Get PriceVibramech vibrating screens are custom designed for client needs and cover a vast range of sizes and unique process applications Our screen design makes use of Finite Element Method and Strain Gauge Analysis to prove structural integrity Liwell screens are for difficult screening applications where sticky material is screened at small

Get PriceVibrating Screen Separator offered come precision designed to successfully handle the tasks of achieving precision screening operations through the support of vibrating motor that comes fitted in a base of the support of motor helps in creating desired vibration frequency in a way that allows screening of the processed material

Get PriceDec 21 2020Vibrating Screens Vibrating Conveyors Screener Motion Vibration Discs on these machines look very different in one application to the next as they are designed for the specific materials the screen will handle Disc screens are usually employed to scalp remove overs in high volume applications though they re also sometimes

Get PriceVibrating Screens Vibrating screens are used to segregate feeds comprising solid and crushed ores down to approximately 210μm and are also applicable to both dried and wetted feed The high frequency vibration screens operate at varying 0 to 25 degrees and can go up to a maximum of 45 degrees

Get PriceThe circular vibrating screen is widely used in product classification of mining building materials transportation energy chemical and other industries The big difference between circular vibrating screen and linear vibrating screen is that one does circular motion and the other does the linear motion Circular vibrating screen structure

Get PriceThe sloped rectangular vibrating machine screen design provides greater screening capacity with less space than other conventional inclined vibrating screens this design is ideal for high rates screening applications such as separating plastics pellets screening silica sand recycling rubber crumbs pulp and paper screening frac sand minerals stones building materials mining etc

Get PriceThe screen surface load SSL caused by granular materials is an important factor affecting the structural performance of vibrating screen Based on virtual experiment a multi objective

Get Price2024 08 10 Polyweb Urethane Screen Panel minimum aperture also 2024 07 06 Promotion Discount Price for Polyurethane Fine Screen Panel 2024 05 05 Causes and treatment methods for scratches on the belt of the iron remover 2024 05 05 How To Choose Multideck High Frequency Screen 2024 02 14 What is the difference between high frequency

Get Price1 day ago3YK1548 3 layer screen the screen area is ㎡ and the processing capacity is 162m/h 4YK1548 4 layer screen the screen area is ㎡ and the processing capacity is 162m/h 2 Linear vibrating screen The characteristics of the linear vibrating screen are high efficiency simple structure convenient maintenance low power

Get PriceIn mining operations vibrating screen is one of the screening equipment that is often used Nowadays most of the vibrating screens on the market are linear vibrating screens and circular vibrating screens These two types of vibrating screens can also be divided into various types according to the screening materials usage scenarios and output

Get PriceLaboratory sieves are a kind of mining vibrating screen that is suitable for dry sieving of moist fine difficult sieved materials The vibrating screen has the characteristics of large amplitude large vibration intensity low frequency and elastic screen surface The opening ratio is kept throughout the working process so the screening

Get PriceLearn about FMC/Link Belt Vibrating Screens and Syntron Grizzly Bar Screens sold by Williams Company Founded in 1989 to serve Coal Construction Aggregates Power Generation Wood and Recycling industries with bulk materials handling and processing equipment

Get PriceWhen you need reliable scalping sizing desliming or rinsing of processed materials trust the heavy duty Tabor Incline TI screen Available in single double and triple deck configurations Elgin s vibrating screens deliver maximum durability with customizable features and accessories Linear motion inclined screens are used primarily

Get PriceMetso Lokotrack Mobile Scalping Screen Lokotrack mobile scalping screen makes the scalping of sticky recycling material look easy The design principle has been simple to optimise capacity in demanding scalping and to minimise unprofitable time on site The has an aggressive 15mm eccentric throw and can handle a wide

Get PriceWith a vibrating screen as part of your installation separating sieving and sorting of a wide range of materials can be done efficiently and precisely At Antha Pol we are experienced in designing and manufacturing vibrating screen equipment for recycling and bulk handling industries Depending on your specific requirements a customized

Get PriceOct 29 20212022 08 10 Polyweb Urethane Screen Panel minimum aperture also 2024 07 06 Promotion Discount Price for Polyurethane Fine Screen Panel 2024 05 05 Causes and treatment methods for scratches on the belt of the iron remover 2024 05 05 How To Choose Multideck High Frequency Screen 2024 02 14 What is the difference between high frequency

Get PriceMaterial Of Construction Vibrating Screen Cloths are made of Spring Steel high and medium carbon steel Stainless Steel of all grades and any other desired metal Vibrating Screen Cloth is custom designed in Case Plungers and Vibrating Rods are needed to insert within the spread of the screen cloth to guard against the tearing of cloth

Get PriceSieve Screen 4 Layer 1500 x 4500mm R 379 excl VAT Sieve Grizzly Bar 4900 x 1100mm R 385 excl VAT Sieve Grizzly Bar 6000 x 1300mm R 478 excl VAT

Get PriceOur vibrating screens are designed for various applications It can be manufactured in mild steel stainless steel for food and pharmaceutical applications Abrasion resistant liners with countersunk bolts minimize feeder pan material buildup Variety of liner materials available including VRN 200/400 Poly Urethane and steel back lined

Get PriceVibra Screw screens are used for subdividing materials into various size ranges and for screening out of oversized or undersize particles as well as the removal of impurities or foreign bodies They can be supplied for capacities of a few lbs/hr or up to 600 tons/hr

Get Price1 Vibrating screen YA is of double decks to four decks whose moving track is round 2 The moving track of material is very long the size of material can be separated into several specifications 3 It adopts cylinder style inspiring vibrator device and eccentric shaft to adjust It has the features of reliable structure strong vibrating

Get PriceThe body moves in a circular motion in order to screen out the material DY 600 Vibrating Screen /DY 800 Vibrating Screen/DY 1000 Vibrating Screen Price 598$ 898$ round powder pebble vibrating screen machine sieve/vibro saparater/sifter machine/round vibrating screen

Get Price6 Vibrating screen is a vibrating system Thus screen deck mass plus material mass on deck is total mass which is resting on springs This is vibrated by exciting force Mass spring stiffness damping factor hysteresis losses and exciting force are complementary and together will create desired vibration

Get PriceConstruction materials for Vibratory Screens includes mild steel 304 or 316 stainless steel Mild steel troughs can be painted in process specific painting systems Stainless steel troughs can be finished as per requirements Operation angles are critical to screen performance

Get PriceThe Vibroset Vibrating Screener makes a perfect scalping screen for asphalt rock grain processing and a wide variety of industrial processes Vibroset Vibrating Screener SMICO Vibratory Screens CALL NOW

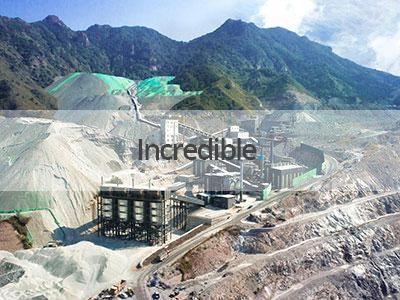

Get PriceIncredible has successfully built lots of crushing plants, grinding plants and metal ore dressing plants for our customers.

With over 30 years of experience, we become a renowned manufacturer in the stone crushing and mineral grinding industry. Headquartered in Shanghai, China, our expansive factory spans over 120 hectares, empowering us to cater to the production demands of global customers.